| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | Concrete Batching Machine |

|---|---|

| Brand Name: | Mind |

| Certification: | ISO, CE |

| Place of Origin: | Henan, China |

| MOQ: | One set/sets |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 100 Set/sets per Month |

| Delivery Time: | 7-20 Working Days |

| Packaging Details: | 1. Plastic Films + 2. Wooden Case |

| Condition: | New |

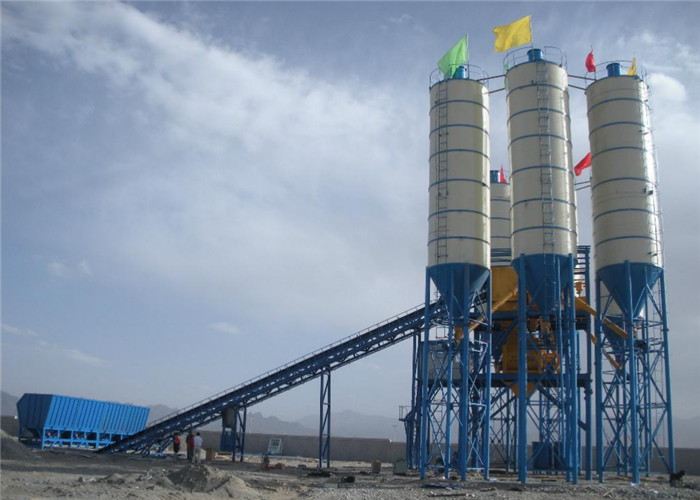

| Product name: | HZS50 Stationary Precast Concrete Batching Plant |

| Color: | Blue,Customer Request |

| Application: | Construction Projects,Engineering & Construction machinery |

| Control system: | PLC+PC,totally automatic |

| Discharging height: | ≥3.9m |

| Cement silo: | 50t/100t/150t.customized |

| Keyword: | concrete batching machine,Fixed Concrete Batching Plant |

The concrete mixing station not only has an excellent mixing machine, but also has a variety of sophisticated accessories, such as screw conveyors, metering sensors, pneumatic components, etc. These components ensure the high reliability of the concrete mixing station during operation, accurate measurement skills and Extremely long service life. At the same time, each maintenance and repair part of the concrete mixing station is equipped with a walking platform or a check ladder, and has sufficient control space. The mixing host can be equipped with a high-pressure automatic cleaning system, which has the functions of lack of oil and over-temperature automatic alarm function, which is convenient for equipment maintenance.

| Model | HZS50 | |

| The whole station | Max.Productivity | 50m³/h |

| Discharge Height | 1.5-3.8m | |

| Working Cycle | 72s | |

| Dimension (LxWXH) | 15922x13500x17750mm | |

| Power | 90kw | |

| Concrete Mixer | JS1000 | |

| Batching Machine | PLD1600 | |

| Pneumatic System | Air Compressor Model | 1.5-7 |

| Nominal Displacement | 1.67m³/h | |

| Rated Discharge Pressure | 0.8mpa | |

| Motor Power | 7.5kw | |

| Measurment Accuracy of Weighing system | Aggregate | ±2% |

| Cement | ±1% | |

| Water | ±1% | |

| Admixture | ±1% | |

The hopper concrete mixing plant saves between one-half and two-thirds of the site area compared to the usual oblique belt conveyor. It adopts modular structure and modular unit, which is very convenient for installation and relocation. When the customer purchases the equipment, our factory will prepare some frequently-changed accessories for the customer, so that the customer can handle the fault in time. The operation is simple and convenient. The Chinese and English menus show that the status of each device is simulated and displayed with an audible and visual alarm. When working at the mixing station, after only a small number of buttons are operated, the entire work process is transferred to the computer control.

|