| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | Carton Making Machine |

|---|---|

| Brand Name: | Starpack |

| Model Number: | TP-CR |

| Certification: | CE Certificate, Patent Certificate |

| Place of Origin: | Foshan,, China |

| MOQ: | 1 Set |

| Price: | Negotication |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3 sets per Month |

| Delivery Time: | 60-90 days |

| Packaging Details: | Steel Base with Carton Box and Film Wrapping |

| Name: | Corrugated Carton Making Machine |

| Type: | For Make Corrugated Cartons |

| Voltage: | 380V 50HZ or Custom |

| Condition: | Brand New |

| Service: | Engineers Available To Service Machinery Overseas, Video Technical Support, Field Installation, Online Support, Commissioning And Training |

| Warranty: | 1 Years After Installation |

| Loading Port: | Guangzhou Of China |

| Automatic Type: | Full Automatic, High Speed |

| Color: | Custom |

| Company Info. |

| Guangdong Toprint Machinery Co., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

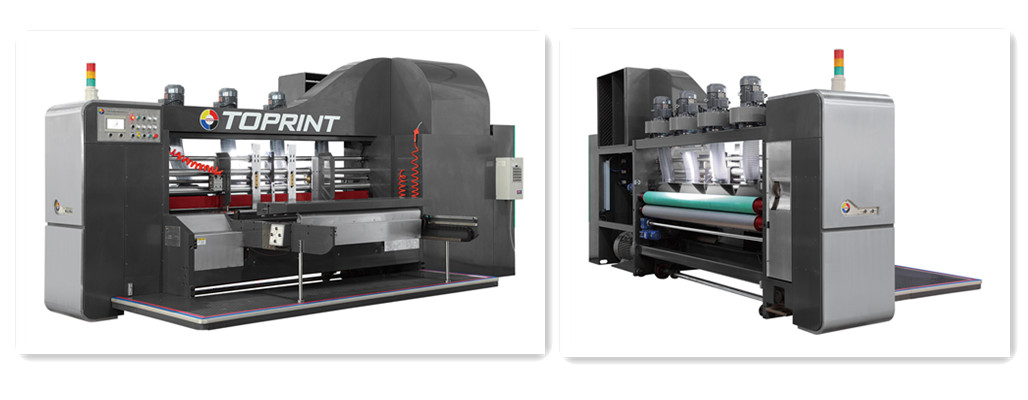

Carton Box Casemaker from China High Speed Servo Control Corrugated Carton Making Machine Folder Gluer Machine

General Specifications

TP-CR Series open & close type flexo folder gluer represents of Quality, Consistency, Efficiency and Economic.

High speed inline top flexo print casemaker with down folding provides a complete carton boxes producing solutions.

The machine is designed and made to high quality and safety standard, stable and consistency high printing quality maximize the production efficiency.

MAIN PARAMETERS

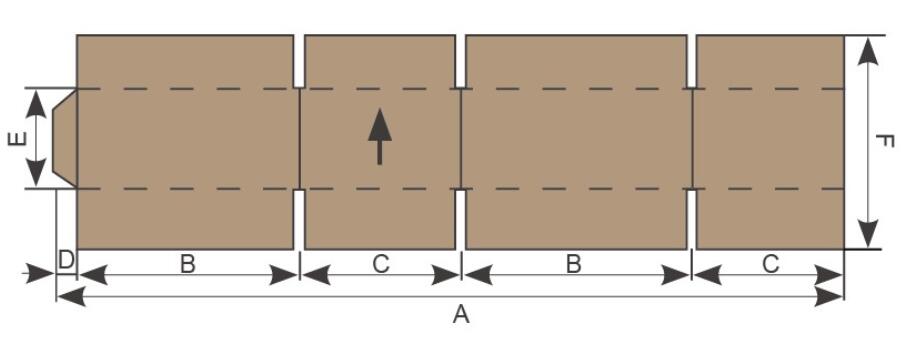

Model Parameters (MM) | 0920 | 1224 | ||

| Max.Sheet Size (FxA) | 890x2000 | 1190x2400 | ||

| Skip Feed Size (FxA) | 1200x2000 | 1400x2400 | ||

| Min.Sheet Size (FxA) | 280x780 | 380x780 | ||

| Max.Printing Area (FxA) | 890x2360 | 1190x2360 | ||

| Top Speed (Sheet/min) | 300 | 250 | ||

| Economic Speed (sheet/min) | 120-250 | 120-200 | ||

| Max. Slot Depth Size | 300 | 300 | ||

| Min. Box Height Size (E) | 110 | 110 | ||

| Max. Die-Cutting Area (FxA) | 850x2350 | 1150x2350 | ||

| (Max. size) (B+C) | ≤980 mm | ≤1180 mm | ||

| (Min. size) (B+C) | ≥370mm | ≥380mm | ||

| (Max. size) (B) | 880mm | 1030mm | ||

| (Min. size) (B) | 270mm | 280mm | ||

| (Max. size) (C) | 710mm | 900mm | ||

| (Min. size) (C) | 100mm | 100mm | ||

| (Glue Flap Width) (D) | ≤40mm | ≤40mm | ||

| Sheet Thickness | 1.5-11 | 1.5-11 | ||

| Printing Plate Thickness (Sponge + Film + Plate) | 7.2 | 7.2 | ||

| Main Working Power (KW) | 4 Colors Slotter Die-cutter + Inline Folder Gluer | 70+40 | 70+40 | |

| Total Power(KW) | 4 Colors Slotter Die-cutter + Inline Folder Gluer | 100+51 | 100+51 | |

| Dimension (mm) | 4 Colors Slotter Die-cutter | 10500x5000x2530 | 10500x5200x2630 | |

| Inline Folder Gluer | 14300x2500x2650 | 14300x2600x2650 | ||

| Frame Thickness | Flexo Printer | 60mm | 60mm | |

| Folder Gluer | 40mm | 40mm | ||

PLC control with HMI touch screen for operation.

Lead edge feeding transmission, 3 or 4 shafts feeding box.

Benefits for all kind of cardboard.

Motorized side guides, front guide and backstop guide.

Available for skip feed.

Two groups of feeding roller, upper roller covered with rubber, lower roller engraved with slot.

Motorized units open and close with alarm.

Gaps are motorized control with digital display.

Frequency inverter drive with variable suction control.

Non-crush Feeding System is Optional

PLC control with HMI touch screen for operation.

Top print, Vacuum transfer system.

All transmission wheels are ceramic coated.

All wheels bearing with independent grease fitting for lubrication.

Gaps adjusted motorized control with digital display.

Servo control of register.

USA ARO diaphragm ink pump.

Automatic washing system.

Auto zero- set for printing position.

Laser engraved ceramic anilox roll, 250-350LPI.

Rubber Roller as standard, and chamber blade system is Optional.

Surveillance System for checking cardboard transmission situation.

PLC control with HMI touch screen for operation.

8 shaft structure, pre-creasing, big-creasing, thin-creasing, slotting.

Dual slotting system Optional.

Auto zero- set for slotting knife.

Slotting Register servo control.

Gaps adjusted computerized control with digital display.

Middle knife movement.

Slotting boss movements adopts linear guiding system match with ball screw, smooth movement.

Slotting boss adopts opposite insert structure, stable moving.

PLC control with HMI touch screen for operation.

Die-cutting cylinder adopts Heavy duty structure.

Servo control of register.

Line speed compensation frequency control.

Grinding system is used for prolong life time of anvil cover.

Auto zero- set for die cutting position.

PLC control with HMI touch screen for operation.

Top printing with down folding.

Independent servo control of folding gluer side belts, speed can be adjust freely.

Independent servo control of guiding wheels for tracking box folding edge to make sure accurate folding.

Main belts with vacuum blower for accurate transmission.

Full servo control of counter ejector jobs to make sure precision counting and ejecting.

|