| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | Permanent Magnetic Separator |

|---|---|

| Brand Name: | JC |

| Model Number: | JC-01 |

| Place of Origin: | CHINA |

| MOQ: | 1 |

| Price: | 100,000 |

| Payment Terms: | T/T,BA |

| Supply Ability: | Strong |

| Delivery Time: | 2 to 4 weeks |

| Packaging Details: | Base support + Wooden case |

| Power supply voltage: | 220V/380V |

| Ore feeding method: | Magnetic separator with bottom ore feeding |

| Product characteristics: | Iron removal |

| Processing capacity: | High |

| Characteristics: | Stable magnetic force |

| Installation method: | Mechanical or manual |

| Company Info. |

| Jinci(Tianjin)Magnetics Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

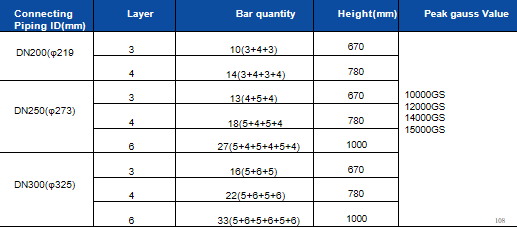

Permanent magnetic pipeline iron remover and magnetic separation equipment for removing iron impurities, used in grain machinery and ore dressing.

Selection Guide

Selection Based on Impurity Removal Rate Requirements and Site Environment:For places with high iron removal requirements,such as coal transportation ports and large thermal power plants,choose permanent magnetic separators with high magnetic field strength and good iron removal effects.In harsh environments like dusty and humid conditions,select equipment with good sealing performance and strong environmental adaptability.

Consideration of Installation Location:When installed at the head of the belt conveyor,the materials are in a loose state when leaving the belt,which is conducive to iron removal.When installed in the middle of the belt conveyor,non-magnetic flat idlers can be used to improve the iron removal effect.Special designs are required for special site environments.

Configuration for Multi-Stage Iron Removal:When multi-stage iron removal is adopted,the iron removal capacity of the subsequent stage should be stronger than that of the previous stage to ensure the iron removal effect.

Classification and Characteristics

Pipeline Permanent Magnetic Separator:Mainly used for iron removal

in pipeline materials.During the flow of materials in the

pipeline,magnetic impurities are adsorbed onto the permanent

magnets on the pipeline wall.It is commonly used for iron removal

of powdery or granular materials in industries such as chemical

engineering and food.It has the advantages of easy

installation,space-saving,and good iron removal effect.

Flat Permanent Magnetic Separator:With a simple structure,it is

usually installed below chutes or vibrating feeders to remove

ferromagnetic impurities from non-magnetic materials.It is suitable

for situations where the iron

Working Principle

By leveraging the high-intensity magnetic field region formed by permanent magnets,when materials containing magnetic impurities pass through the magnetic field area of the separator,the magnetic impurities are attracted to the surface or interior of the separator under the action of the magnetic force,thus separating from the materials and achieving the purpose of iron removal.

|