| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | Steel Raw Material |

|---|---|

| Brand Name: | EVEREST |

| Model Number: | 904L Stainless Steel |

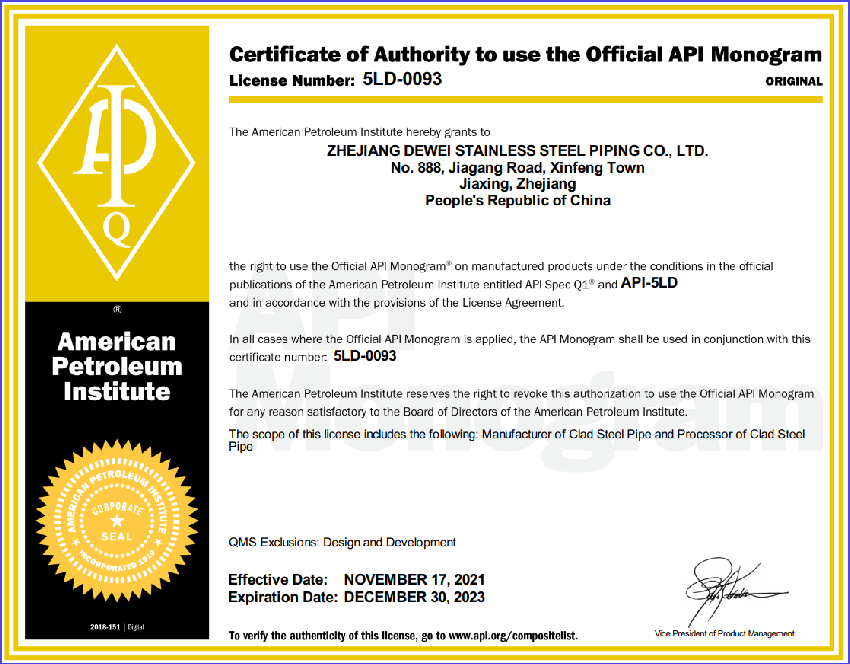

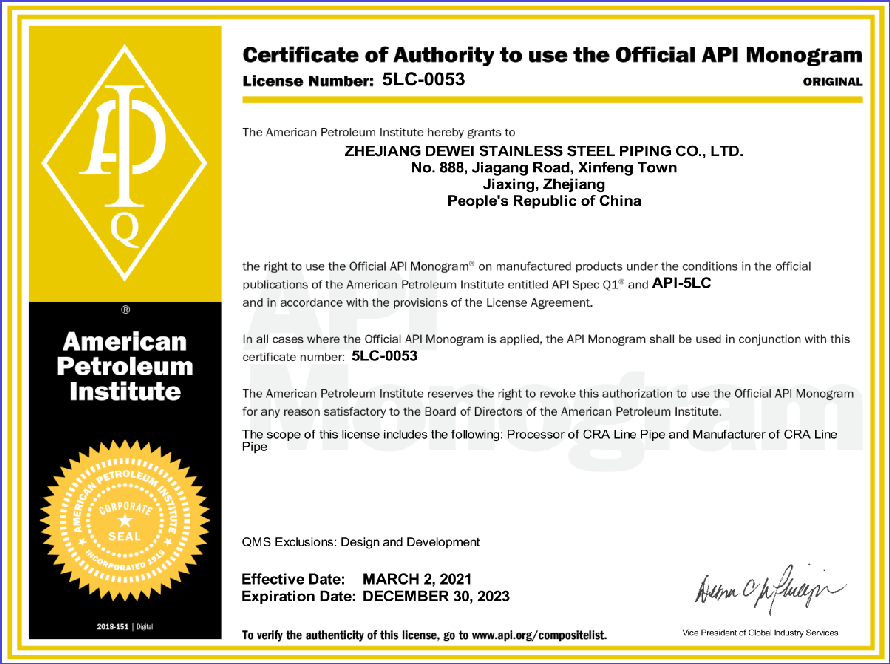

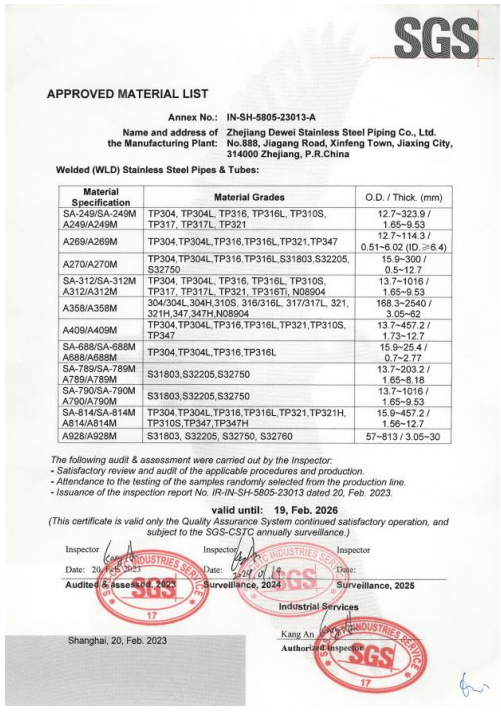

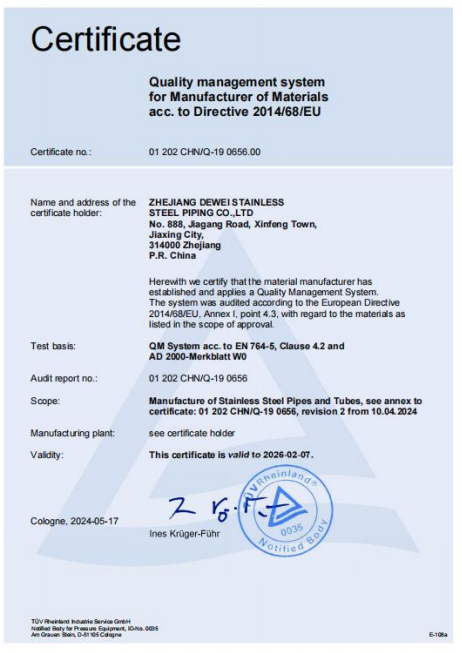

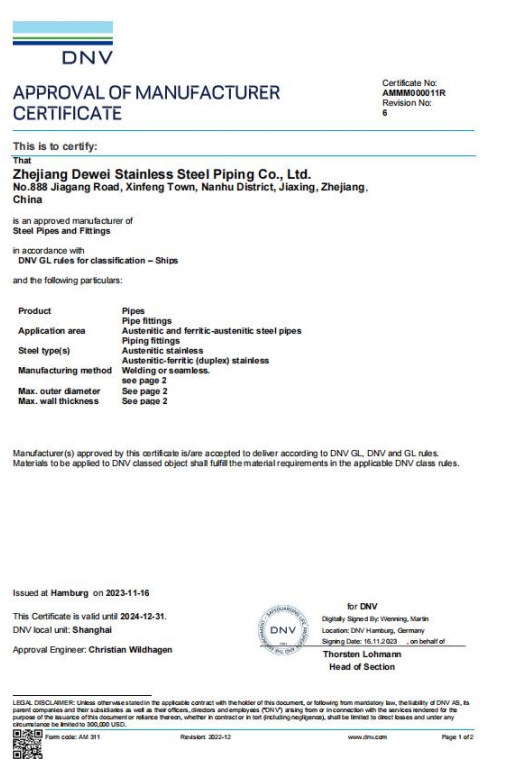

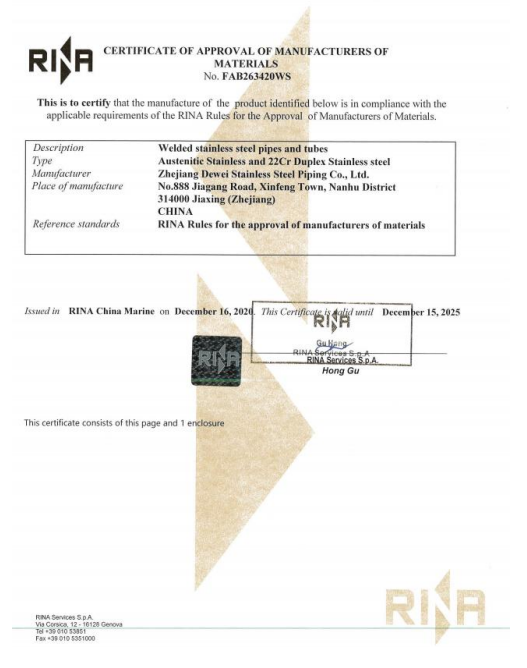

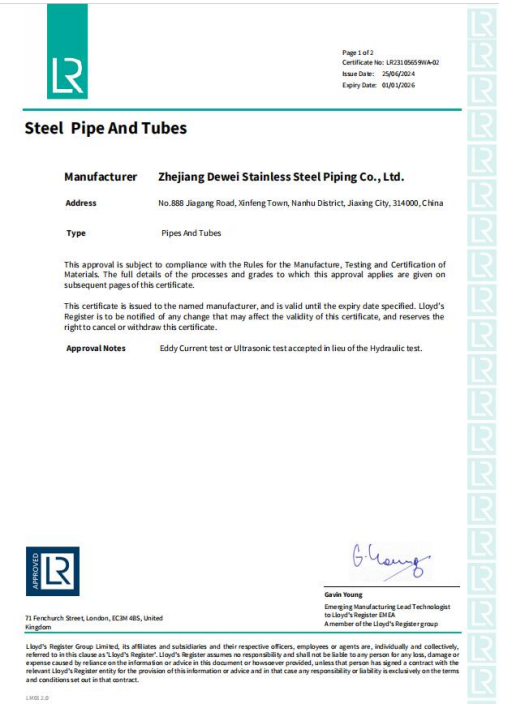

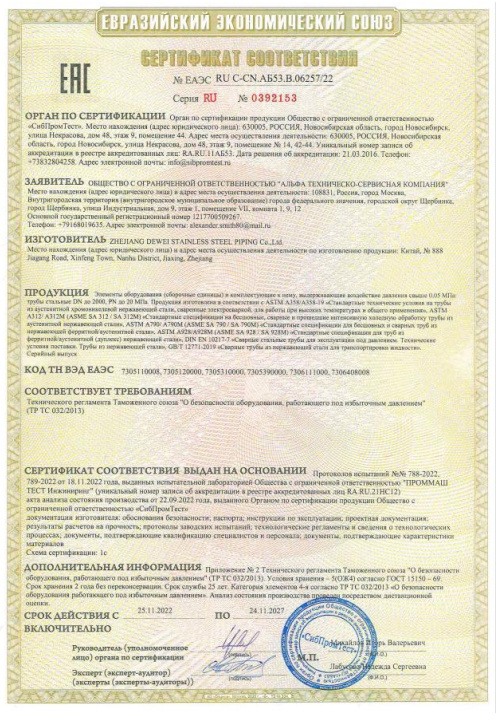

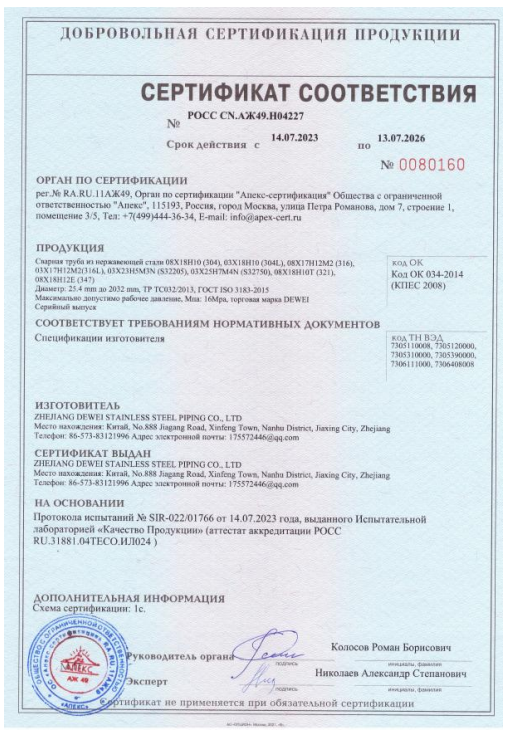

| Certification: | lS09001,IS014001, ISO45001, (TS ) Grade A, PED2014/68/EU,AP1 5LC, API 5LD, ASME, CCS, LR, DNV , BVRINA and ABS. |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T |

| Supply Ability: | 18,000 tons/year |

| Delivery Time: | 10-21working days |

| Packaging Details: | according to customers' demand |

| Product: | High-Chromium Nickel Molybdenum and Copper Content 904L Stainless Steel Raw Material for Pharmaceutical Industries |

| Chemical Composition: | Cr (19-23%), Ni (23-28%), Mo (4-5%), Cu (1-2%), C (≤0.02%), Fe (Balance) |

| Hardness (Hardened): | 160-220 |

| Tensile Strength (Rm): | ≥490 MPa |

| Yield Strength (Rp0.2): | ≥220 MPa |

| Elongation (A5): | ≥35% |

| Density: | 7.95 g/cm³ |

| PREN (Pitting Resistance): | ≥36 |

| Max Service Temp: | 400°C (752°F) |

| Product Features: | Unmatched Corrosion Resistance,High Mechanical Strength,Excellent Fabrication Versatility,Hygienic & Cleanability,Eco-Friendly & Sustainable,etc. |

| Core Advantages: | Superior to 316L/317L,Global Certifications,Custom Solutions,Fast Deliver,Technical Support,etc. |

| Typical Applications: | Chemical & Petrochemical,Pharmaceutical,Marine & Offshore,Pulp & Paper,Energy,Food & Beverage,etc. |

| Company Info. |

| Everest Technology (Wuxi) Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

High-Chromium Nickel Molybdenum and Copper Content 904L Stainless Steel Raw Material for Pharmaceutical Industries

Product Overview:

904L Stainless Steel is a high-performance super austenitic alloy renowned for its exceptional resistance to sulfuric acid, chlorides, and other aggressive media. With elevated chromium (19-23%), nickel (23-28%), molybdenum (4-5%), and copper (1-2%) content, it outperforms standard 316L and 317L stainless steels in highly corrosive environments. Widely used in chemical processing, marine engineering, and pharmaceutical industries, 904L combines durability with versatility, making it a top-tier choice for critical applications demanding longevity and reliability.

Key Physical Properties:

Chemical Composition: Cr (19-23%), Ni (23-28%), Mo (4-5%), Cu (1-2%), C (≤0.02%), Fe (Balance)

Hardness (HB): 160-220

Tensile Strength (Rm): ≥490 MPa

Yield Strength (Rp0.2): ≥220 MPa

Elongation (A5): ≥35%

Density: 7.95 g/cm³

PREN (Pitting Resistance): ≥36

Max Service Temp: 400°C (752°F)

Product Features:

Unmatched Corrosion Resistance

Resists sulfuric acid, phosphoric acid, chlorides, and seawater, even in high-concentration and high-temperature conditions.

Immune to stress corrosion cracking (SCC) and crevice corrosion in chloride-rich environments.

High Mechanical Strength

Maintains structural integrity under high-pressure and thermal cycling, ideal for chemical reactors and heat exchangers.

Superior to 316L in both strength and corrosion resistance.

Excellent Fabrication Versatility

Weldable via TIG, MIG, and SAW methods (use 904L filler wire).

Compatible with cold working and machining (annealing recommended post-processing).

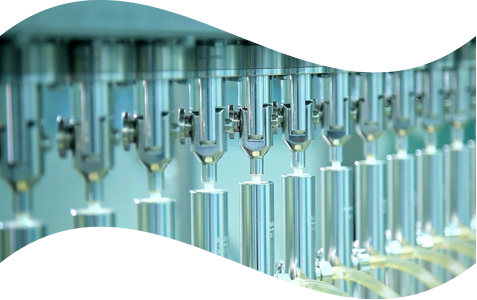

Hygienic & Cleanability

Smooth, non-porous surface resists bacterial growth, perfect for pharmaceutical and food processing equipment.

Eco-Friendly & Sustainable

100% recyclable and RoHS-compliant, aligning with green manufacturing initiatives.

Core Advantages:

Typical Applications:

Chemical & Petrochemical: Sulfuric acid reactors, pickling tanks, heat exchangers, distillation columns.

Pharmaceutical: CIP (Clean-in-Place) systems, bioreactors, solvent storage tanks.

Marine & Offshore: Seawater piping, desalination units, offshore platform components.

Pulp & Paper: Bleaching equipment, digesters, pulp handling systems.

Energy: Flue gas scrubbers, geothermal energy systems, LNG processing.

Food & Beverage: Vinegar production tanks, citrus juice processing lines.

Why Choose Our 904L Stainless Steel?

Quality Inspection:

Quality Management Department is establshed in the enterprise, which is responsible for the implementation of quallty management acrossall sectors, including QC, QA and implement and supervise various management system. The company reviews the Quality Manual byconducting management reviews annually to confirm its conformance, effectiveness and suitability.

HENGLI Petrochemical 40 million / year ton of oil refining integration project | ZHEJIANG Petrochemical 40 million / year ton of oil refining integration project | LIANYUNGANG Petrochemical 3.2 million tons / young hydrocarbon comprehensive | YISHENG New Material The 6.6 million tons / year of the PTA project | CNOOC Huizhou Refining & Chemical Co Huilian Phase II, 22 million / year ton of oil refining Reconstruction and expansion project | Sinopec Zhenhai Refining & Chemical Company 1.2 million / year ton ethylene renovation and expansion project | Wanhua Chemical 480,000 tons / year bisphenol A integration project | GUANGXI Huayi New Materials Integration project of new chemical materials | CNOOC Shell The SMPO & POD project | China AtlantoShaanxi Coal Chemical Industry: 1.8 million tons / year ethylene glycol project |

|  |  |  |  |  |  |  |  |  |

| Hainan Huasheng 2.26 million tons / year non-photogamic polycarbonate project | Shenghong Refining The 16 million tons / year oil refining project | Anhui Haoyuan Chemical Industry 300,000 tons / year ethylene glycol project | Heilongjiang Longyou Petrochemical Company5.5 million tons / year heavy oil catalytic pyrolysis project | HuaLu Hengsheng 500,000 tons / year ethylene glycol project | Baofeng Energy600,000 tons / year methanol to olefin project | Jiangnan Shipyard (98000m³ liquefied ethane ship, etc.) Brand number: 316 / 316L, delivery time: 2020.12 | Keppel shipyard in Singapore (FLNG ship) Brand number: 316 / 316L, delivery time: 2020.1 | Guangzhou Wenchong Shipyard (Super double-phase steel

desulfurization tower) Brand number: S32750 Delivery time: 2021.3 | CSSC Dalian (FPSO, MV31, etc.) Brand number: 316L, etc., delivery date, 2019.8 |

|  |  |  |  |  |  |  |  |  |

| 725 Institute of China Shipbuilding Industry (Cu-Ni alloy Tube) | Nantong COCSO Shipyard (FSRU ship module) | CIMC Raffles (Drilling Rig) | CNOOC Orient 13-2 (Lined pipe) | CNOOC Bozhong 19-6 (Lined Pipe) | Petrobras MODEC FPSO (COSCO Shipping) | CNOOC Guangxi LNG, storage and transportation storage Brand number: 304 / 304L | CNOOC Zhejiang LNG Phase II Brand number: 304 / 304L | Sinopec Shandong LNG Phase II Brand number: 304 / 304L | LIANYUNGANG Petrochemical A 4X160000m³ low-temperature ethane storage tank Brand number: 304 / 304L Specification: 813X12.7MM Delivery time: 2020.9 |

|  |  |  |  |  |  |  |  |  |

| Sinopec Luoyang Institute Wenzhou LNG terminal Brand number: 304 / 304L Specification: 219.1~711X12.7MM Delivery time: 2022.3 | Huatai Shengfu 160,000 m ³ low-temperature ethane storage tank Brand number: 304 / 304L Specification: 219~508X9.53MM | YAMAL LNG Brand number: 304 / 304L Specification: 406~914X9.53MM | Beijing Maiden Voyage | Oriental Hope | Sichuan Yongxiang 70,000 tons / year high purity polysilicon project | Xinjiang Daquan 25,000 tons / year high purity polysilicon project | Eagle Central China Paper Industry 500,000 tons of box board project | Guangxi Sun Paper 3.5 million tons of forest pulp and paper integration project | APP for Asian pulp and paper Chemical machine pulp and sewage treatment project |

|  |  |  |  |  |  |  |  |  |

TCL Shenzhen Huaxing Optoelectronics semiconductor clean pipeline project | Beijing Daxing Airport | Hong Kong-Zhuhai-Macau/Macao Bridge Tubes used for stainless steel construction | CNNC Xiapu nuclear Power Plant Fast reactor demonstration project of CNNC 2.3 | CONBA Stainless steel pipe for pharmaceutical engineering | Shenghong Refining Stainless steel associated heat pipe | Hangzhou Sewage Treatment Plant Stainless steel pipe for backwash purification unit | Qilu Pharmaceutical Fluid stainless steel pipe for raw material delivery | Zijin Mining Wet copper smelting, stainless steel sewage pipe | ect |

|  |  |  |  |  |  |  |  | …… |

Certificate

| API-5LD AUTHENTICATION | American Petroleum Institute API 5LC Certificate | ASME Certificate in the United States | EU PED&AD2000 certificate | ABS classification society certification certificate in the United States | DNV Det Norske Veritas Certificate | RINA Italian Bureau of Shipping Certificate | BV French Bureau of Shipping certification | LR Lloyd's Register Certificate of Approval | Customs Union EAC Certificate | Russian GOST certificate |

|  |  |  |  |  |  |  |  |  |  |

| Raw Material Vendors | Cooperation Partners |

|  |

Packing and Shipping:

This peoduct is carefully packaged to ensure its safe delivery to you. It is wrapped in protective packaging material to prevent any scratches or damage during transit.

For shipping, we use trusted delivery services to make sure your product arrives promptly and in excellent condition. You can track your order to know exactly when it will reach you.

Conquer Corrosion with 904L – The Ultimate Choice for Harsh

Environments!

From chemical plants to offshore platforms, 904L stainless steel

ensures decades of reliable service. Request aquote today – empower

your projects with alloy excellence!

|