| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | Tank Welding Machine |

|---|---|

| Brand Name: | WINCOO |

| Model Number: | WQ-III |

| Certification: | CE,ISO,CCC,SGS,CE ; C C C |

| Place of Origin: | CHINA |

| MOQ: | 1 |

| Price: | USD 1200~3000 1 SET |

| Payment Terms: | L/C,D/P,T/T,D/A,Western Union,MoneyGram |

| Supply Ability: | 300 sets 1 month |

| Delivery Time: | 20 |

| Packaging Details: | Export packages |

| After-sales service provided: | Engineers available to service machinery overseas,Field maintenance and repair service,Video technical support,Field installation,commissioning and training |

| Voltage: | 380V,220/380V,220V/380V/440V/600V,380v/50hz or customized,As customer requirement |

| Usage: | Carbon Steel welding,seam welding of metal material.,girth seam and longitudinal seam welding,Automatic straight seam welding,welding robot |

| Dimensions: | Depends,1000*1000*1400,not yet,to order,400*800*900 mm |

| Weight: | Depends,3.5kg/4.5kg/5.5kg,1T,264KG,800KG |

| Type: | Other,zx7-200 zx7-250 mma-200 mma-250 arc-200 arc-250,MIG Welders,TIG Welders |

| Rated duty cycle: | 100%,50%,60-100%,25%,60% |

| Current: | 300A,100KVA,to order,630A,1-1000A |

| Warranty: | 1 Year,15month,one year after installation |

| Rated capacity: | Depends,3KVA,100KVA,to order,31kW |

| Machine type: | Welding Manipulator,Seam welding machine,Tank welding machine |

| Color: | yellow,blue or customized,Blue,Orange and blue,as customer requirement |

| Condition: | New |

| Name: | fabric welding machine,transformer tank automatic welding machine,Automatic Flange Circular Tank Welding Machine( by certificated ),Complete Welding Equipment For Semi Trailer Tank,Steel Pipe/Tank/Cylinder Column and Boom Welding Machine Manipulator |

| Welding speed: | 5~50mm/s,200-650mm/min,50-1000m/min |

| Application: | Welding Repair Machine,carbon steel/steel/stainless steel/alloy steel,circular seam welding,welding longitudinal seam on tank |

| Power(w): | 1500,6.5KVA 7.6KVA 9.6KVA,As different model machine,35KVA |

| Arc current: | 60-630A,200,140,120,180 |

| Company Info. |

| Wincoo Engineering Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

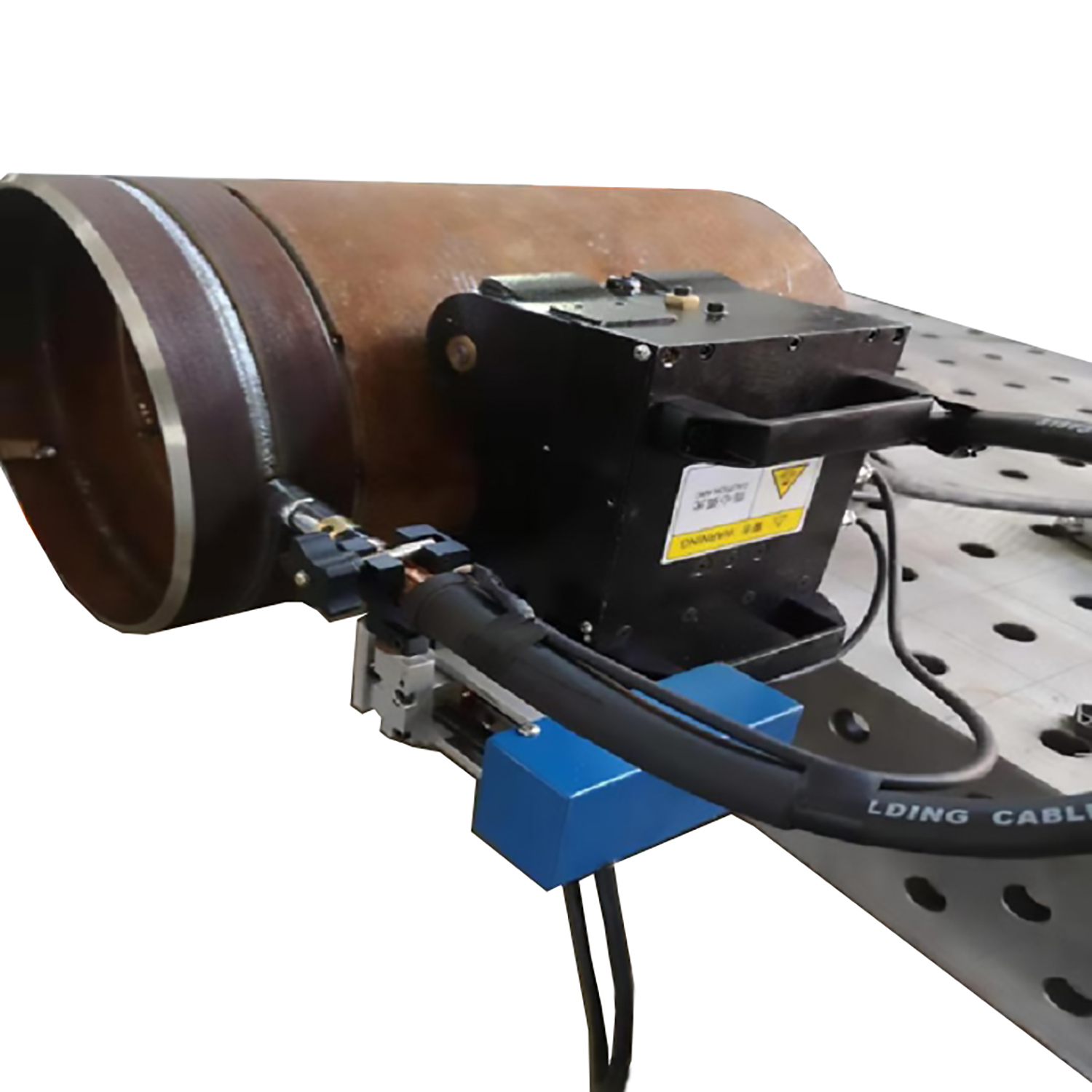

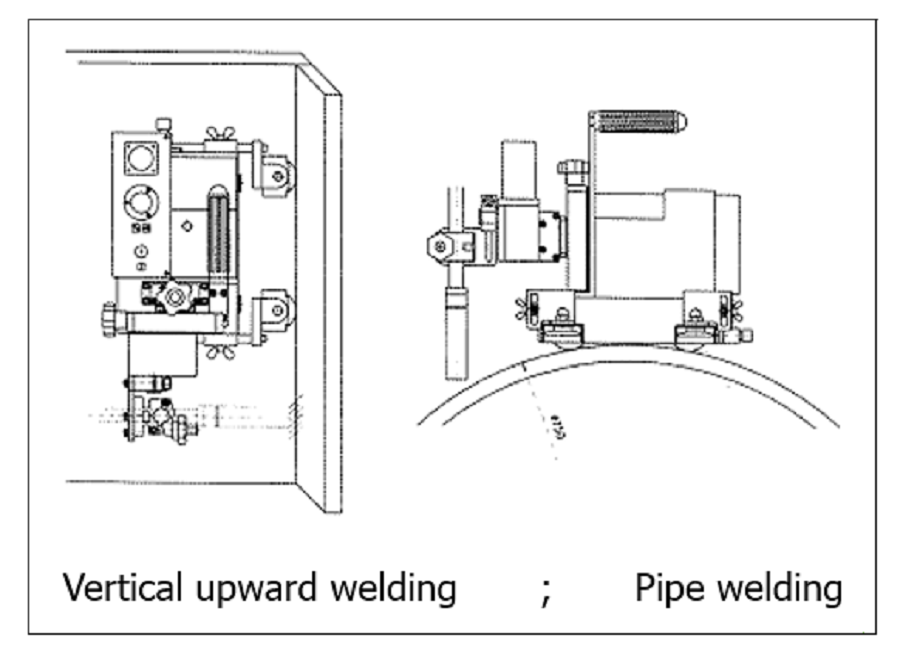

The full-position automatic pipeline welding machine is a cutting-edge solution designed for high-efficiency, precision welding of long-distance oil, gas, and liquid transmission pipelines. Engineered to operate in all welding positions (1G to 6G), this equipment ensures seamless joint quality across horizontal, vertical, overhead, and inclined orientations – a critical requirement for cross-country pipeline projects spanning diverse terrains.across horizontal, vertical, overhead, and inclined orientations – a critical requirement for cross-country pipeline projects spanning diverse terrains.

Technical Parameter:

| Items | Parameter | Note | |

| Tractor | Power supply | AC 220V | |

| Size | 240×330×310 | W×L×H | |

| Weight | 16Kg | Including swinger | |

| Moving mode | Four-wheel drive | Magnet-wheel | |

| Walking speed | 0∼700mm/min | ||

| Swing motor | DC24V 18RPM | ||

| Adjustable range of welding gun | Up and down | ||

| Before and after | 85mm | ||

| Operating Angle adjustment range | 360° | ||

| Carry out Angle adjustment range | 0° | ||

| Control | Operating function | Swing mode |  |

| Swing speed | 0-10RPM(Show with scale) | ||

| Swing scope | 0-±10°(Show with scale) | ||

| Left and right residence time adjustment | 0-2S(Show with scale) | ||

| Central range of movement | 0-±8° | ||

| Inching wire feeding | |||

| Walking starts/stops | |||

| Welding current/voltage control | |||

| Choice of walking direction | |||

| Walking speed regulation | 0∼1000mm/min(Show with scale) | ||

| Welding/non-welding options | |||

Key Features:

Omni-Directional Welding Capability

Equipped with a programmable rotating arm and adaptive tracking

system, the machine maintains stable arc characteristics and

consistent bead formation regardless of pipe orientation. The

dual-motor drive system enables precise control at 0.1° resolution

for complex weld paths.

Multi-Process Compatibility

Supports pulsed MIG/MAG, TIG, and flux-cored welding processes,

accommodating API 5L X60-X100 grade steels with diameters ranging

from 8" to 56". The modular design allows quick process switching

for root, hot, fill, and cap passes.

Environmental Resilience

IP65-rated enclosure protects against dust, moisture (-30°C to 50°C

operation), and electromagnetic interference, making it ideal for

Arctic environments and desert installations.

Smart Control System

Integrated with real-time weld parameter adjustment (voltage:

15-40V, current: 50-500A) and defect detection algorithms. The HMI

touchscreen provides visual guidance for orbital welding sequences

and stores 200+ preset programs.

Applications:

Cross-country oil/gas trunk lines

Subsea pipeline tie-ins

Mountainous terrain bypass welding

Pipeline maintenance hot-tap operations

|