| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | Automatic Soldering Robot |

|---|---|

| Brand Name: | HSTECH |

| Model Number: | HS-200W |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 200 sets per month |

| Delivery Time: | 3-5 work days |

| Packaging Details: | Wooden Case |

| Product Name: | Semi-auto Soldering Station |

| Application: | Electronic Assembly |

| Working Platform: | Single Station |

| Output Power: | 200W |

| Machine Size:: | L410*W350*H500MM |

| Weight: | 15 KG |

| Company Info. |

| Shenzhen Hansome Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

High-Efficiency 200W Semi-Auto Soldering Station Automatic

Soldering Robot

Introduction

The semi-automatic soldering machine stands as a testament to the

electronics industry's steadfast pursuit of efficiency and

precision. As a crucial element in electronic component

manufacturing lines, this equipment excels in stability and

effectiveness, significantly enhancing both production output and

product quality. With the swift evolution of the electronics

sector, the semi-automatic soldering machine has emerged as an

indispensable tool, seamlessly integrating into modern

manufacturing processes.

Features

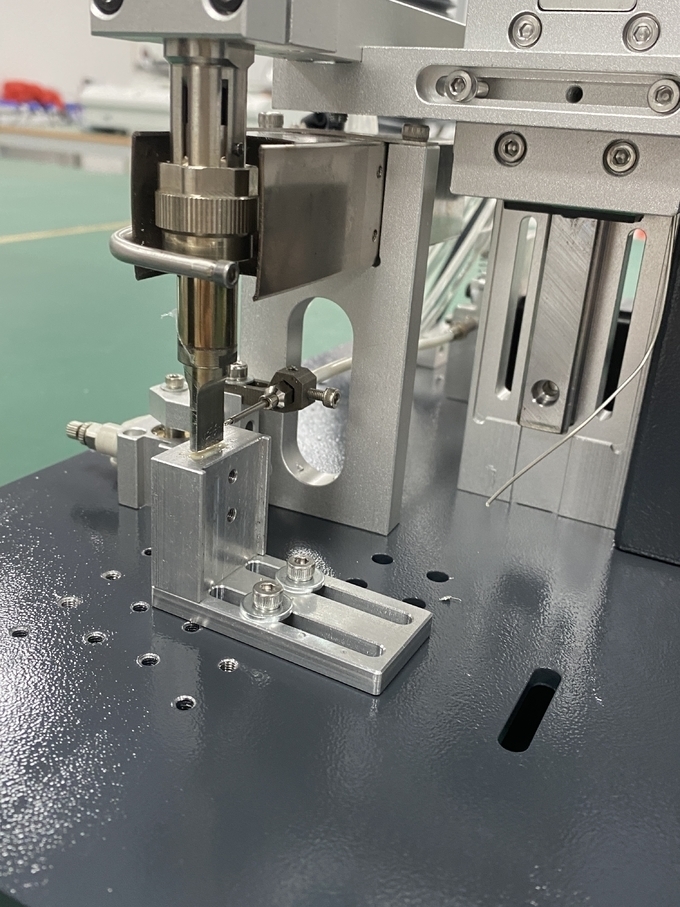

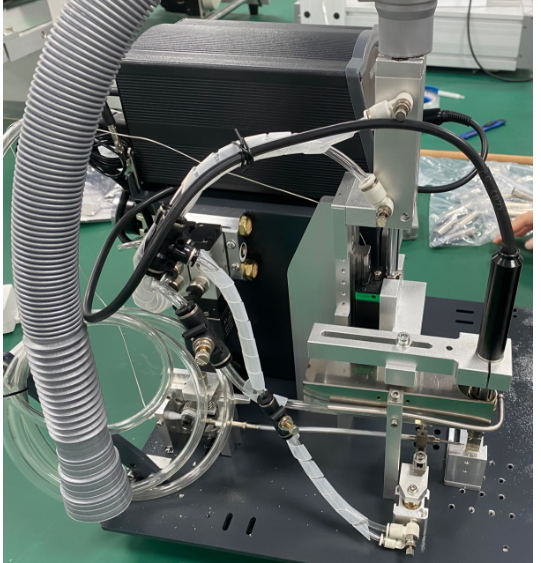

Semi-Automatic Operation:

The operator retains manual control over the soldering process, yet

the equipment incorporates automated features such as automatic tin

feeding and heating to enhance efficiency.

Temperature Control:

Equipped with a high-precision temperature control system, it can

be adjusted to meet the specific requirements of different solders

and components.

Versatility:

This system supports a range of soldering technologies, including

wave soldering, reflow soldering, and manual soldering, allowing it

to adapt to diverse production needs.

Ease of Use:

The user-friendly control interface, typically featuring a display

and straightforward operation buttons, facilitates easy setup and

operation.

Application Areas:

Electronic Manufacturing:

Widely utilized in small-batch production and prototype

development, it is suitable for soldering various types of

electronic components.

Repair and Maintenance:

Ideal for repairing electronic equipment, enabling convenient

component replacement and re-soldering.

Advantages:

Efficiency Improvement:

Semi-automatic operation reduces the time required for manual

soldering, thereby enhancing production efficiency.

Consistency:

Automated functions ensure consistent soldering quality, minimizing

human errors.

Flexibility:

Suitable for a multitude of soldering tasks, it can cater to

different production requirements.

| Product Name | Semi-auto soldering station |

| Model No. | HS-668 |

| Power supply | Single phase, 220V 50/60Hz |

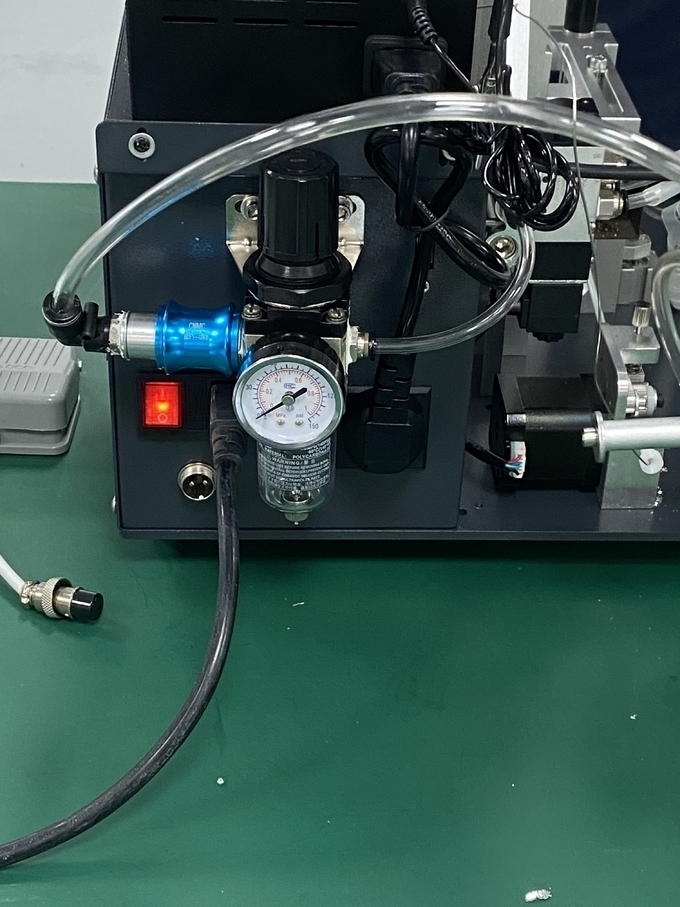

| Air pressure | 0.2-0.6MPa(Use clean dry air) |

| Control mode | PLC+touch screen |

| Temperature | (-10)-(+60℃)No wind, no dust |

| Soldering control switch | Pedal switch |

| Machine size | L410*W350*H500MM |

| Weight | 15 KG |

About Packaging

|