| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | Paper Making Machine |

|---|---|

| Brand Name: | Huatao |

| Model Number: | HT 450-800 |

| Certification: | SGS,ISO CE |

| Place of Origin: | China |

| MOQ: | 1sets |

| Price: | 1200-7000usd/set |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 5000 SETS per Month |

| Delivery Time: | 30-60 days |

| Packaging Details: | Wooden Case |

| Product Name: | Alloy Refiner Rotor And Stator For Paper Mill |

| Material: | Alloy,Cast Iron Chrome Coated,17-4pH,Special S.S |

| OD: | 450-800MM |

| Hardness: | Max 68HRC |

| Suitable Machine: | Vairous Conical Refiner |

| Application: | Paper Mill |

| Company Info. |

| HUATAO LOVER LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

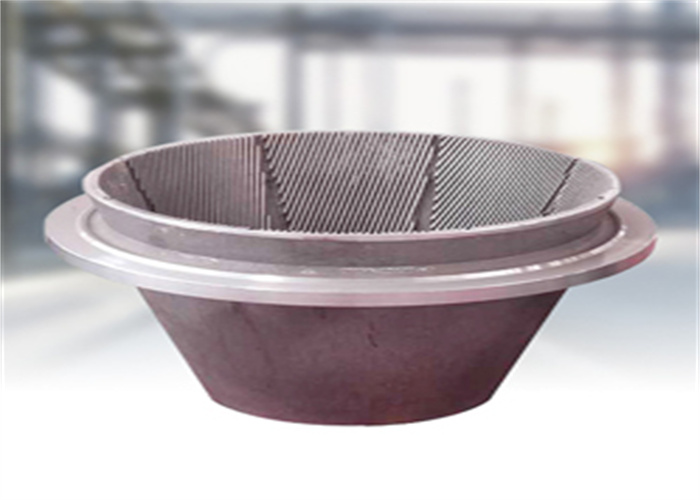

Alloy Refiner Rotor And Stator For Paper Mill

Description For Alloy Refiner Rotor And Stator For Paper Mill

Alloy Refiner Rotor And Stator For Paper Mill is mainly used for coarse beating refining and re-pulping of broke

and waster paper. It is available for long fiber pulp such as

cotton, wood. The equipment is furnished with an automatic control

system and can beat with a constant power of constant energy

consumption. The beating effect is stable.

Conical Refiner construction of Rotor and stator is conical.

The pulp beating disc refiner rotor and stator is the "heart" of the double disc refiner and the conical refiner. In addition to the need for excellent wear resistance and impact toughness, the rationality of the tooth profile will directly affect the beating performance. "Three points for paper making, seven points for beating", to process different slurries, different indexes and the number of refiners in series should choose different tooth types. Therefore, the study of the relationship between the theory of specific blade edge load, the theory of specific surface load, rheological effect and beating performance, and the non-isolated understanding of the relationship between the various elements, is important to ensure the fiber bonding strength, filter performance, retention rate, quality of the finished paper and It is very important to save power consumption for beating.

Technical Parameters For Alloy Refiner Rotor And Stator For Paper Mill

| Product name | Alloy Refiner Rotor And Stator For Paper Mill |

| Model | 450-800 |

| Material | Alloy,cast iron chrome coated,17-4PH,special S.S,high carbon S.S,High chrome alloy,etc |

| Diameters | 450 mm-800 mm |

| Hardness | 40-68HRC |

| Conical Degree | 40° |

| Suitable Refiner Machine/Defibrator | A-ndritz,V-almet,M-etso,V-oith |

| Applied Industry | Pulp and paper making |

Our Advantages

1.Wide range of metallurgies developed for industry needs.

2.It can be designed according to various of versions and

requirements.

3.Custom designed plates are developed in shortest time.

4.Stronger plates for longer life.

5.Increased Plate Working Lifetime

6.Reduced Plate Breakage

7.Reduced Plate Plugging Problems

8.Reduced Refiner Plate Breaks

9.Lower Furnish Costs

10.Increased Refining Capacity

11.Energy Savings

|