| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | OSB Continuous Press |

|---|---|

| Brand Name: | SufoTech |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | USD+10,000,000.00~20,000,000.00 |

| Packaging Details: | Wooden package |

| Delivery Time: | 10 months |

| Payment Terms: | L/C,T/T |

| Press speed: | Max. 2000 Mm/s |

| Final board width: | 915~2800 Mm |

| Capacity: | 300~1500 M³/d |

| Final board length: | 1830~5490 Mm |

| Final board thickness: | 6~40 Mm |

| Width of production line: | 4,6,7,8,9 Feet |

| Company Info. |

| Suzhou Forestry Technologies Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Durable and Versatile Continuous Press Particle Board Production Line 300~1500m³/day

Fully Automatic 300~1500 Cbm Per Day Particle Board Continuous Press Production Line

Description

Three-layer cross-oriented strand boards, OSB type 3 of 10 mm thick, were industrially manufactured from a mixture of wood species including 50% softwoods, 25% beech, and 25% low hardwoods, using a continuous press line. The effects of line speed and press factor on physical and mechanical properties of OSB/3 (exterior grade) were evaluated, keeping nearly constant the face-core adhesive ratio. The manufactured boards were classified into five groups depending on the pressing parameters. The experimental results showed that all mechanical properties increased, with increasing press factor and decreasing line speed. The ratios of bending strength (MOR) and the modulus of elasticity (MOE) parallel to perpendicular were 1.73 to 1.89 and 2.18 to 2.24, respectively. No significant differences in thickness swell and water absorption were observed. The lowest density was achieved at higher speed, although there was no large variation in densities between groups. Thickness swelling and internal bond after boil test exceeded the EN 300 standard requirements for OSB/3 moisture resistance, excepting a few boards. The results revealed that a correlation between speed and press factor is necessary in order to improve mechanical properties and to keep the physical performance of boards within a limited range of values.

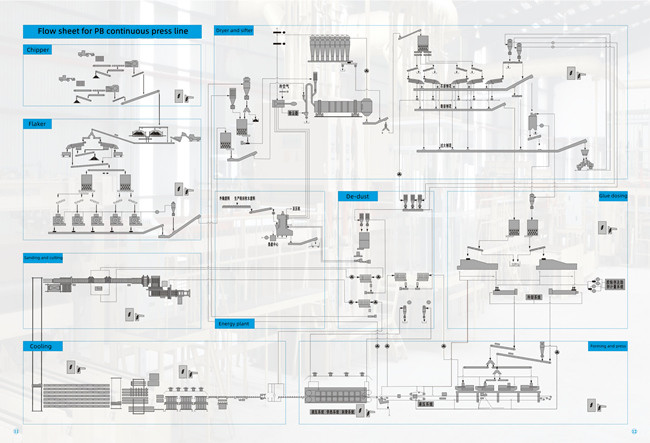

The 300~1500m³/day particle board production line uses raw material through chips preparation, flakes preparation, dring and sitfting, glue dosing system, forming and hot pressing, cooling &trimming and sanding section to make particle board / chipboard. The final size can be 4 x 8, 6 x 8, 6 x 9, 4 x 12, 6 x 12, 6 x 18. The particle board has homogeneous structure, smooth surface, good machining specification and manufacture performance. It is the ideal substitute of nature wood.

Summary of process flow

Main technical data

| Item | Unit | Specification |

| Capacity | m³/d | 300~1500 |

| Width of production line | feet | 4,6,7,8,9 |

| Final board thickness | mm | 6~40 |

| Final board width | mm | 915~2800 |

| Final board length | mm | 1830~5490 |

| Press speed | mm/s | Max. 2000 |

Key equipment of production line

1 High energy efficiency and waste energy can be recycled to save energy

2 More safe due to low oxygen drying to prevent fire

3 Flaker shape will be well maintained

4 Stable flaker moisture

5 Large unit capacity

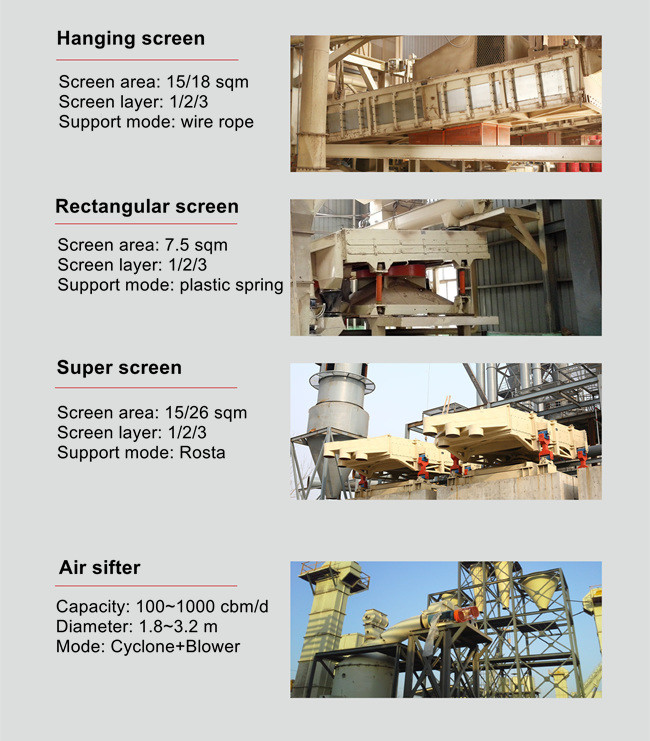

1 Large capacity and good performance

2 Frame screen box makes strong and durable

3 Brilliant elastic vibration support

4 Perfect rotary balance technology

5 Self-clean system with jumping balls

6 Stable running and long lifetime

7 Compact structure and less space required

1 Feeding crosswise— real-time regional control technology

2 Volume equal silo— ensure consistent bulk density

3 Aerodynamics— perfect balance of positive/negative pressure airflow

4 Airflow regulation system— artful combination of vertical& horizontal adjustment

5 Airflow surface forming— fine and smooth surface

6 Advanced control technology— high precision lengthwise and crosswise density

1 Crosswise feeding— real-time regional control technology

2 More delicate diamond rollers— ensure forming precision

3 Positive/negative pressure assistant airflow— ensure better fine surface

4 Core cage roller forming— uniform core mat structure

5 Advanced control technology— high precision lengthwise and crosswise density

|