| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | YYC Rack and Pinion |

|---|---|

| Brand Name: | YYC |

| Model Number: | CHTMH02010 |

| Certification: | CE,ISO |

| Place of Origin: | China |

| MOQ: | Negotiation |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100,000 pcs per month |

| Delivery Time: | Negotiation |

| Packaging Details: | Standard export carton packing, wooden case, foam board inside for protection. |

| Product Name: | YYC Rack And Pinion |

| Material: | S50C |

| Number of Teeth: | 150 |

| Hardness: | HRC 50-55° |

| Quality grade: | DIN 10 |

| Weight: | 4.1kg |

| Core Components: | Gear |

| Applicable Industries: | CNC tool machine, milling machine, drilling machine, lathe, machining center, cutting machinery |

| Company Info. |

| Jiangsu Zane Machinery Technology Co.,ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

YYC Rack and Pinion is a highly durable and reliable Rack-and-Pinion-System designed to meet the highest level of industrial automation requirements. YYC Rack and Pinion is a superior Rack-and-Pinion-Coupling that provides maximum performance for any industrial application. YYC Rack and Pinion is designed for maximum efficiency and reliability, making it an ideal choice for industrial automation applications. The Rack-and-Pinion-Mechanism of YYC Rack and Pinion makes it a perfect fit for any industrial setting, offering superior operation and control.

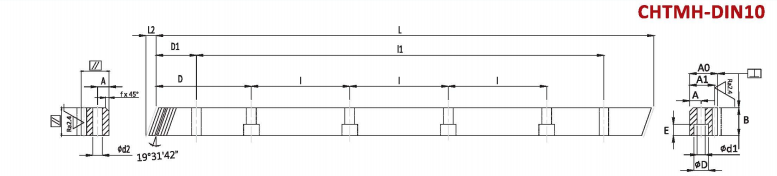

Code | Module | L | L2 | No. of Teeth | B | A0 | Al | D 1 | No. of Holes | A | 0dl | 0D | E | DI | 11 | 0d2 | f | Fta kN | KG | |

| CHTMH01510-DIN10 | 1.5 | 1000 | 6.00 | 200 | 17 | 17 | 15.5 | 62.5 | 125 | 8 | 7 | 6 | 9.5 | 7 | 31.7 | 936.6 | 5.7 | 1.5 | 3.18 | 2.1 |

| CHTMH02010-DIN10 | 2 | 1000 | 8.50 | 150 | 24 | 24 | 22 | 62.5 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 | 2 | 5.98 | 4.1 |

| CHTMH02020-DIN10 | 2 | 2000 | 8.50 | 300 | 24 | 24 | 22 | 62.5 | 125 | 16 | 8 | 7 | 11 | 7 | 31.7 | 1936.6 | 5.7 | 2 | 5.98 | 8.2 |

| CHTMH03010-DIN10 | 3 | 1000 | 10.30 | 100 | 29 | 29 | 26 | 62.5 | 125 | 8 | 9 | 10 | 15 | 9 | 35.0 | 930.0 | 7.7 | 2 | 10.83 | 6.0 |

| CHTMH03020-DIN10 | 3 | 2000 | 10.30 | 200 | 29 | 29 | 26 | 62.5 | 125 | 16 | 9 | 10 | 15 | 9 | 35.0 | 1930.0 | 7.7 | 2 | 10.83 | 12.0 |

| CHTMH04010-DIN10 | 4 | 1000 | 13.80 | 75 | 39 | 39 | 35 | 62.5 | 125 | 8 | 12 | 10 | 15 | 9 | 33.3 | 933.4 | 7.7 | 2 | 19.42 | 10.8 |

| CHTMH04020-DIN10 | 4 | 2000 | 13.80 | 150 | 39 | 39 | 35 | 62.5 | 125 | 16 | 12 | 10 | 15 | 9 | 33.3 | 1933.4 | 7.7 | 2 | 19.42 | 21.6 |

| CHTMH05010-DIN10 | 5 | 1000 | 17.40 | 60 | 49 | 39 | 34 | 62.5 | 125 | 8 | 12 | 14 | 20 | 13 | 37.5 | 925.0 | 11.7 | 3 | 30.51 | 13.6 |

| CHTMH05020-DIN10 | 5 | 2000 | 17.40 | 120 | 49 | 39 | 34 | 62.5 | 125 | 16 | 12 | 14 | 20 | 13 | 37.5 | 1925.0 | 11.7 | 3 | 30.51 | 27.2 |

| CHTMH06010-DIN10 | 6 | 1000 | 20.90 | 50 | 59 | 49 | 43 | 62.5 | 125 | 8 | 16 | 18 | 26 | 17 | 37.5 | 925.0 | 15.7 | 3 | 44.08 | 20.5 |

| CHTMH06020-DIN10 | 6 | 2000 | 20.90 | 100 | 59 | 49 | 43 | 62.5 | 125 | 16 | 16 | 18 | 26 | 17 | 37.5 | 1925.0 | 15.7 | 3 | 44.08 | 41,1 |

| CHTMH08010-DIN10 | 8 | 960 | 28.00 | 36 | 79 | 79 | 71 | 60 | 120 | 8 | 25 | 22 | 33 | 21 | 120.0 | 720.0 | 19.7 | 4 | 78.69 | 42.6 |

| CHTMH08020-DIN10 | 8 | 1920 | 28.00 | 72 | 79 | 79 | 71 | 60 | 120 | 16 | 25 | 22 | 33 | 21 | 120.0 | 1680.0 | 19.7 | 4 | 78.69 | 85.1 |

| CHTMH10010-DIN10 | 10 | 1000 | 35.11 | 30 | 99 | 99 | 89 | 62.5 | 125 | 8 | 32 | 33 | 48 | 32 | 125.0 | 750.0 | 19.7 | 5 | 123.27 | 69.6 |

1.The grinding rack compared with many imported rack, highlighting the cost performance advantage;

2.Rack not only provides precision quality comparable to European, American and Japanese products;

3.We also direct sales to manufacturers, and have advantages in delivery time and price, which are widely praised by many users in the industry;

4.Heat treatment/no heat treatment, surface grinding/no surface grinding, tooth grinding/no tooth grinding. The same modulus can have many strengths.

|