Q & A:

What chemicals are used to make pulp?

Chemical wood pulp is made by cooking wood chips with chemical solutions in digesters operated at elevated temperature and pressure. The chemicals used are (1) sulfite salts with an excess of sulfur dioxide and (2) caustic soda and sodium sulfide (the kraft process).

What are the types of pulping?

There are four broad categories of pulping processes: chemicaly semi-chemical, chemi-me- chanical, and mechanical pulping. These are in order of increasing mechanical energy required to separate fibers (fiberation) and decreasing reliance on chemical action.

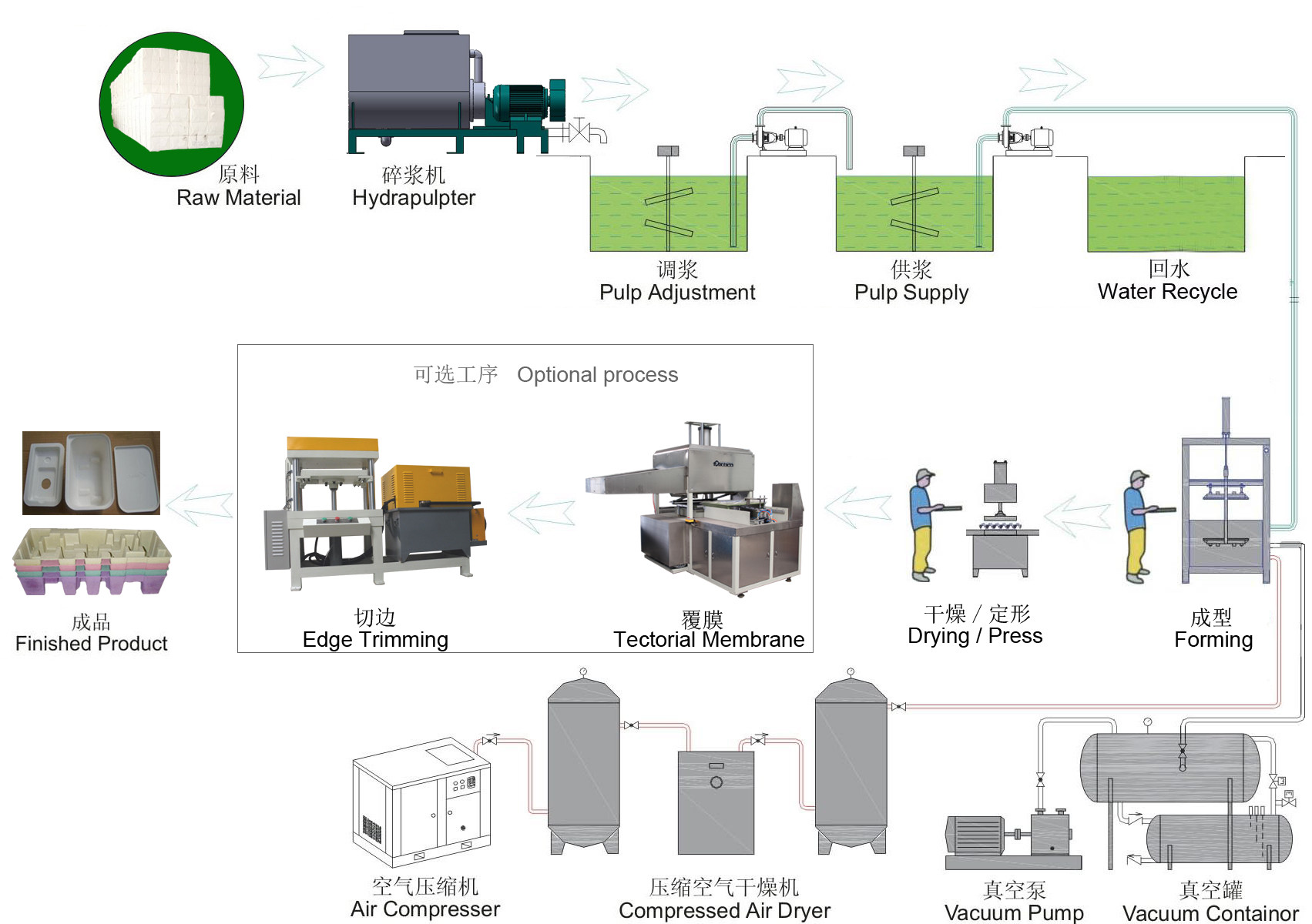

Illustrations of Machine & Product: