| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | Wire Harness Machine |

|---|---|

| Brand Name: | LINQUAN |

| Model Number: | LOONG-860E |

| Certification: | ISO9001, CE |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD 10,000 ~ 500,000 per set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 5 machine per month |

| Delivery Time: | 1-3 Months |

| Packaging Details: | pearl wool+protective film+wooden box |

| Color: | white and grey(customize acceptable) |

| Cutting Length: | 450-9999mm |

| Capacity: | 1000pcs/hr |

| Warranty: | 1 year |

| Power: | 10KW |

| Usage: | both end Cutting , Stripping , Crimping and inserting |

| Compressed Air Connection: | 0.5Mpa |

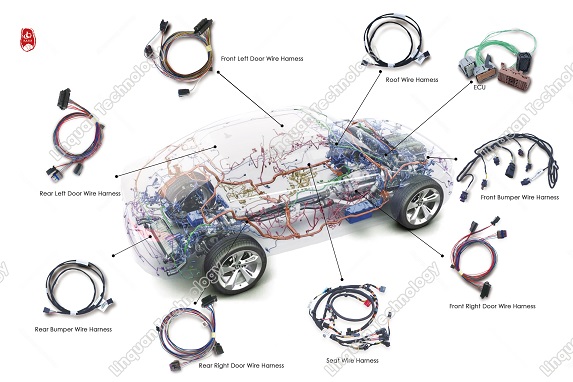

Low Voltage Fully Automatic Wire Harness Manufacturing Modular Design Both-end Crimping and Inserting Machine

Technical Parameters

| Wire Size | 0.13-4.0mm2 |

| Feeding Length | 450-9999mm |

| Stripping Length | Full strip: 0-15mm Half strip: 0-15mm |

| Cutting Precision | Cutting length*0.02mm |

| Stripping Depth | Maximum 3mm |

| Power Source | China - 380V/ 3 Phase / 50Hz Canada - 600V/ 3 Phase / 60Hz USA/Japan - 480V/ 3 Phase / 60Hz Mexico/Honduras - 480V/ 3 Phase / 60Hz Europe - 400V/ 3 Phase / 50Hz |

| Power | 10KW |

| Crimping Capacity | 3 TON presser |

| Wire Selector | Max.50 wire(Different color & cross-section) |

| Wire End Storage | Rotary storage unit with a maximum of 30 storage spaces |

| Air Pressure | 0.5Mpa |

| Connector Types | 30 kinds of the connectors |

Mould Assembly Type | AS40, AS42, AE30(Pneumatic mould can be customized) |

| QC Contents | Wire presence, Wire overload, Terminal presence, Terminal overload, Stripping and crimping visual monitoring, Crimping force monitoring, Insertion & pull-back force monitoring |

| QC Devices | CCD inspection modules, Crimping Force Monitoring (Force sensor), Insertion/Pull-back Force Monitoring (Force sensor), Terminal crimped height measuring instrument, Terminal pull force measuring instrument |

| Efficiency | Both-end crimping and insertion about 1000pcs/hr (Depends on different producing process and the functional module quantity, productivity is different) |

| Functions | Pre-feeding, Wire feeding, Fixed length cutting, Stripping, Both-end crimping, Both-end insertion, Adjusting crimp height on HMI, Unloading defective products through CCD inspection |

Optional | Lin Quan MES System, Laser Inkjet Print, Seal insertion (Max 6 modules), Tinning & Twisting, Wire Stranding, Wire end solidifying, Splicing & welding, Double crimping, Max.12 Crimping Modules (with programmable crimp height), Linear-carrier housing feeding/ Plate-loop conveying housing feeding module (According to customer requirements) |

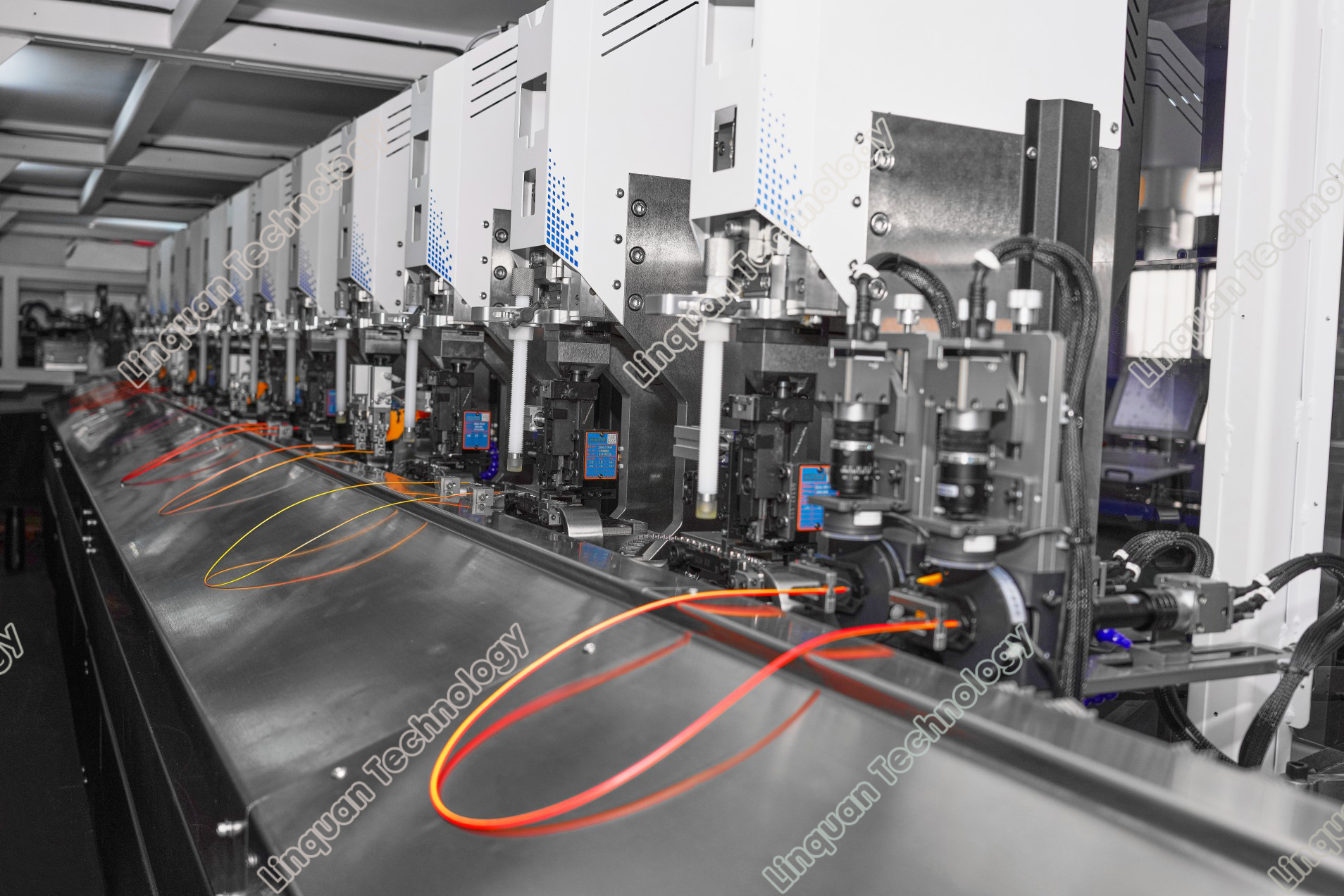

The loong 860 is designed for one-stop,lean manufacturing of complex wire harness with less middle storage and less operator engagement. Thanks to robust automated design and outstanding degree of flexibility, Loong-860 could easily adapt both sequence and batch production mode.

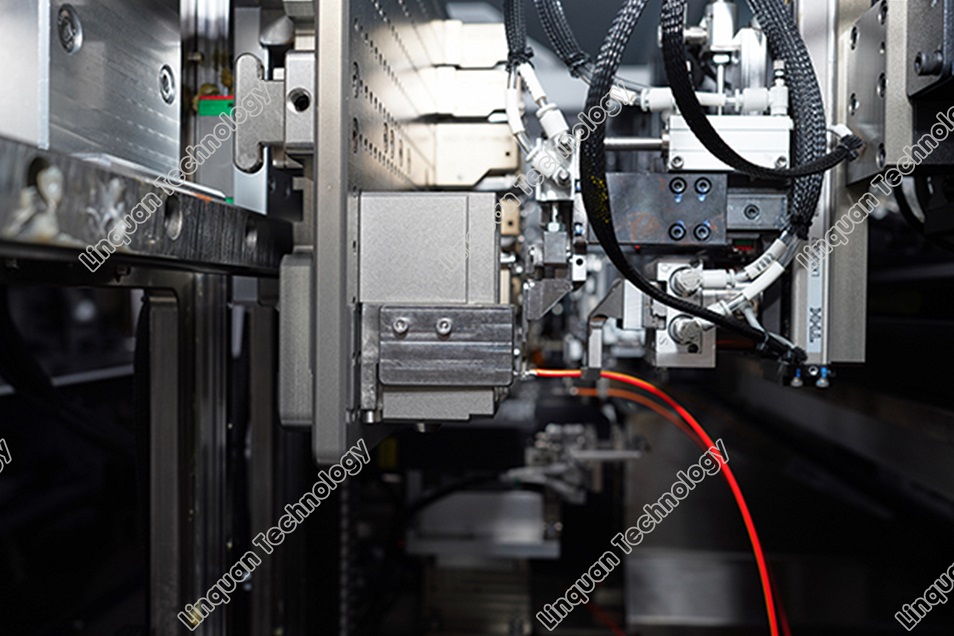

Crimping Module(C202)

Servo-controlled press assures best crimping result.

Integrated with independent crimping force monitoring unit.

Maximum 12 crimping stations could be applied.

Crimping parameters, e.g., crimping height, could be set, adjusted

and displayed at HMI.

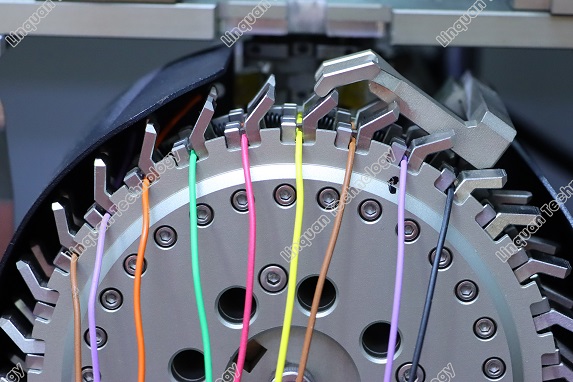

Wire Selector

Compatible for maximum 50 different wires works synchronously.

Tool-free quick guide tube changeover 0.13-4mm²(AWG26-11).

Cutting and Stripping Module

Applying double high-speed blades(V-shape/R-angle blade).

Adjust stripping data with HMI to achieve ultra precision and clean

stripping.

Cutting & stripping variety of cross-section wires without

complicate change-over step.

Untwisting Module

Remove wire twists.

Decline scrap rate.

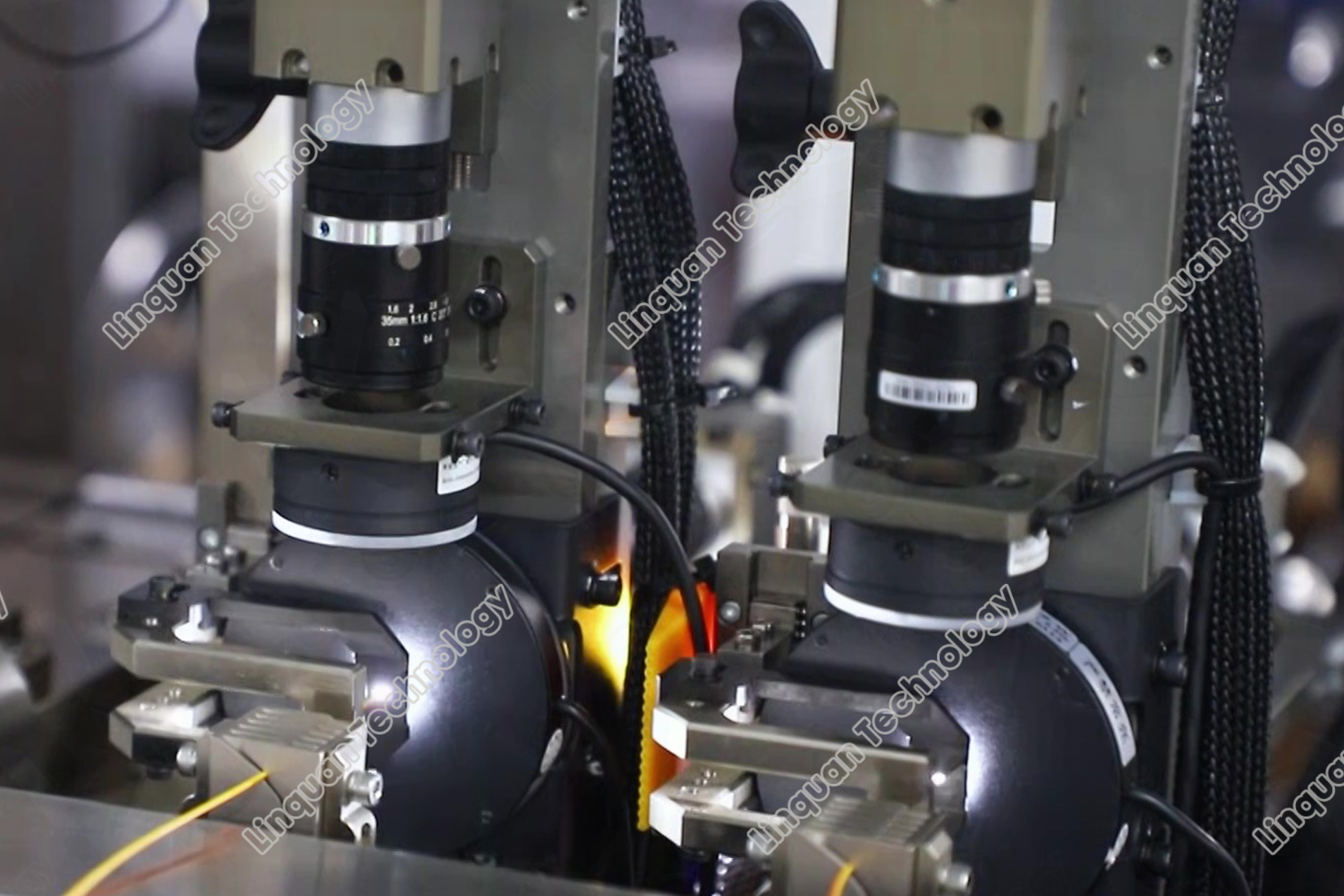

CCD Visual Inspection (TDVM-1)

Integrated QC module, efficient quality monitoring.

Stripping, crimping and center conductor inspection.

Real-time monitoring producing process.

In time detecting scraps.

Wire Storage Unit

30 storage positions.

Optimize insertion sequence: from left to right, button to top.

Breakthrough insertion limitations.

Special design for sophisticate wire harnesses.

Plate-loop Conveying Connector Loading Module

Equipped with two conveying plates, efficient connector reloading.

Versatile connectors loading synchronously.

Enable sequence product producing.

Quick & easy manual final product unloading.

Insertion Module

Dual insertion clamps structure, ensuring insertion accuracy,

stability and efficiency.

Segmented insertion process, integrated insertion and pull-back

force detection, declining scrap rate.

|