| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | Wrap Around Case Packer Machine |

|---|---|

| Brand Name: | V-PAK |

| Model Number: | WKD-LGB10/20 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | Negotiation |

| Payment Terms: | T/T |

| Supply Ability: | 60 sets/year |

| Delivery Time: | 45 working days |

| Packaging Details: | Export-use wooden case |

| Other name: | carton packer machine |

| Compressed air pressure: | 0.5~0.7MPa |

| Usage: | seasoning, cooking oil industry |

| Feature: | environment friendly |

| Color: | customized |

| Packing speed: | 8 /20 cases/min |

Automatic side load wrap around case / carton packer

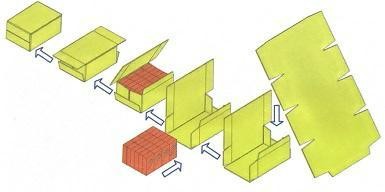

Operating Principle:

1) Bottle/package feeding: Bottles/packages are conveyed onto

infeed conveyor, then through guiding plate to vibrating station to

prevent blocking, after which the bottles or packages will be

separated into different lanes as per customer's requirement by the

separating plates.

2) Flat carton magazine: It can store approximately 200 PCS flat

carton. The flat cartons will be taken one by one by a mechanical

arm with vacuum sucking device an then put on the inclined conveyor

to be conveyed to the filling station.

Description of Wrap Around Case Packer Machine:

Specifications:

| Model | WKD-LGB10 | WKD-LGB20 |

| Power supply | 3P,220V/380V,50/60Hz,10KW | |

| Compressed air pressure | 0.5~0.7MPa | |

| Machine dimension | L5000-6000*W2200*H2000mm | L6000-7000*W2200*H2000mm |

| Case size | L200-500mm*W150-500mm*H100-350mm | |

| Packing speed | 8 cases/min | 20 cases/min |

| Hot melt glue solidify time | 2~3 Sec. | |

Details of Wrap Around Case Packer Machine:

Control logic by PLC Omron/Siemens/Allen Bradley

Product grouping by pneumatically operated collating gate or by

continuous motion combs pulled by servo-driven chains

Hot melt unit: Nordson/Melton/Preo/Robatech

Blank picking on top of blanks stack

Stainless steel / washdown executions available

Complying with UL standards

Case sealing available with top flap outside or inside the case

Electronic card for remote connection and troubleshooting available

Data exchange with corporate SCADA availablei

Centralized lubrication with automatic pump available

Production line:

After sale service:

1. Installation

After equipment reached the workshop of customer, We will arrange

seasoned technician for equipment installation, debug and test

production and at the same time make the equipment reach the rated

producing capacity of the line. Time for installation and debug is

around 15-25 days.

2. Training

Our company offers technology training to customer. The content of

training covers structure and maintenance of equipment, control and

operation of equipment. Training will be arranged in the workshop

of customer. Seasoned technician will guide and establish training

outline. After training, the technician of buyer could master the

operation and maintenance, could adjust the process and treat

different failures.

3. Quality guarantee

We promise that our goods are all new. They're made of suitable

material, adopt new design. The quality, specification and function

all meet the demand of contract. We promise that the products of

this line could last for one year without adding any aseptic

|