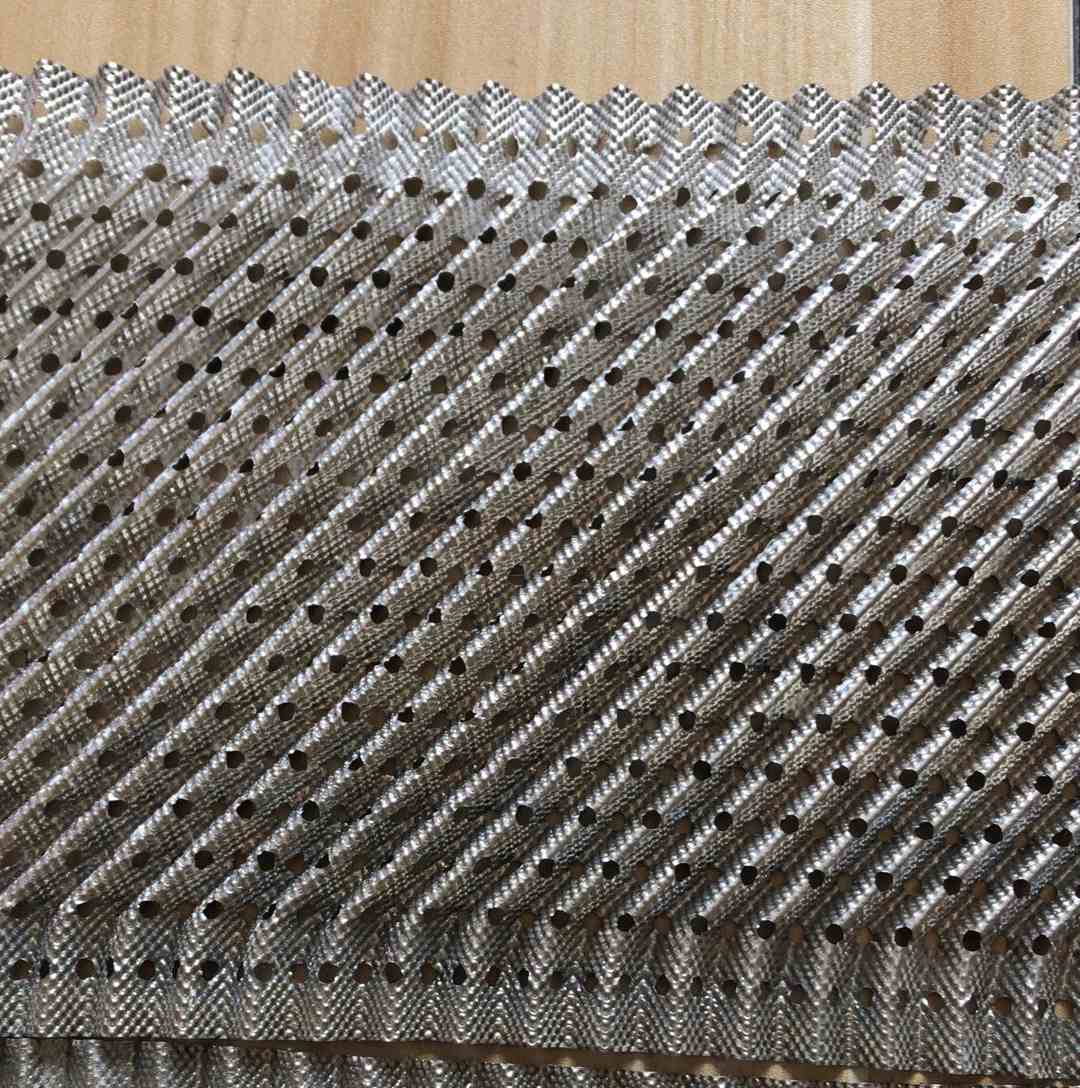

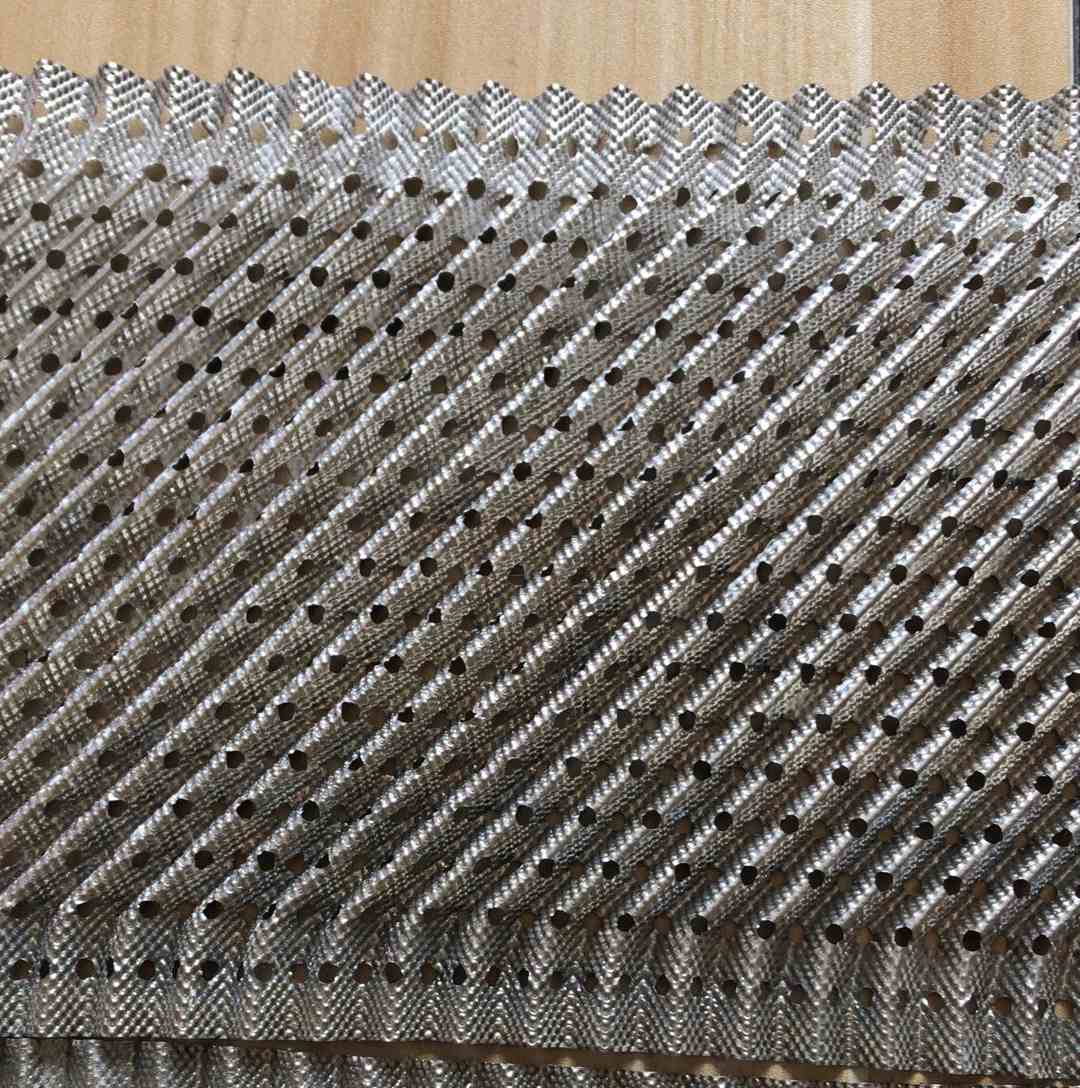

SS304 Structured Packing Exporting Diameter 800mm Mela Pak 250Y

Hualai factory has produced and deliverd more than 1,000 cubic

meters of metal structured packing in the past 3 years. In a

separate workshop with lines of brand new machines, we are able to

make 20-30 cubic meters of high quality tower packing per working

day.

Below are the main types we usually make. Each type has two styles,

different in the wave clination angle to the axis, 30 degrees (X

style) and 45 degrees (Y style). For example, 250Y structured

packing, each wave has a 45 degrees angle to the axis, and the

neighboring plates' waves are vertical to each other. We can also

help make other types such as 450, 252, 452, etc. as per customer

request.

| Type | Surface area | Void fraction | Wave height | Nt | ΔP | Max.F-factor |

| m2/m3 | % | mm | m-1 | Pa/m | m/s.(kg/m3)0.5 |

| 125 | 125 | 98 | 25.4 | 1-2 | 150 | 3 |

| 250 | 250 | 97 | 12.5 | 2-3 | 200 | 2.6 |

| 350 | 350 | 94 | 9 | 2.0-2.5 | 300 | 2 |

| 500 | 500 | 92 | 6.3 | 4-5 | 400 | 1.8 |

| 700 | 700 | 85 | 4.5 | 5-7 | 650 | 1.6 |

I have a customer who is a senior engineer in modular refinery

system. Their oil and gas processing systems are famous in Russian

and Middle Asia market. They are widly used in privately onwed

refinery plants and some pilot testing projects. I am lucky because

he knows well about the structured packing and has in mind the type

wanted. Frankly speaking, though I know some basic features of each

type of the packing, and also can do some simple calculation on it,

it is far away from enough to provide professional suggestions

suitable for the whole system.

During the communication, everything went well except that he

questioned the unit weight of our 250Y column packing, that is

different from a notable manufacturer. Finally we found out the

difference came from the plate thickness. The popular plate

thickness for metal structured packing is now 0.1mm, while his data

was based on 0.2mm plate. We can fabricate 0.2mm plate tower

packing, too. If the flow media is not so corrosive, it is not

necessary to choose the thicker plates with higher cost. Will you

agree with me please?

Generally speaking, the X style has higher through capacity and

lower pressure drop, while the Y style has higher efficiency and a

little higher pressure drop than X style. But the total pressure

drop of structured packing is at a low level. Once I wondered if Y

style will need more material than X style per unit. I had no

samples on hand with the same type and demension to compare. You

can not imagine how I get it out that the X and Y style requires

the same quantity of material. I draw some draft drawings according

to the corrugated plate and meseaured the length of each wave and

get the same result by adding them together. A little joking,

right? That is how I study and learn about our products step by

step.

I have a dream that one day I can provide professional suggestions

to professional buyers of our metal structured packing.

This is An Li in Hualai factory. Welcome your inquiry!