| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | Radiator Recycling Machine |

|---|---|

| Brand Name: | JLNE |

| Model Number: | TF-500 |

| Certification: | CE ISO |

| Place of Origin: | Jiangsu,China |

| MOQ: | 1 set |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 50 sets/year |

| Delivery Time: | 30-40 working days |

| Packaging Details: | FCL |

| Function: | scrap radiator recycling |

| Capacity: | 1000-1500kg/h |

| Output: | copper,aluminum,iron pellet |

| Equipment color: | customized |

| Power: | 140KW |

| Voltage: | customized |

| Control: | PLC |

| After-sales service provided: | Engineers available to service machinery overseas |

Electric Automatic Multi-layer Air Conditioner Radiator Separating Machine

Copper aluminum water tank is the dismantling remains of air

conditioning water tank and car water tank. mainly consisting of

copper tube and aluminum foil.

This car water tank radiator recycling equipment is manufactured by

our factory , the copper alu can be got separately after

cutting,crushing into aluminum copper mixture , then airflow

separating.

It is full automatic process and need one worker.

Application of Radiator separating plant:

The radiator recycling plant is used for crushing and separating

all kind of air conditioner and car water tank radiator with

aluminum fins. Both straight and compressed radiators can be

processed by this recycle plant.

Specifications of Industrial radiator separating machine:

| Model | TF-500 |

| Voltage / Power | 380V / 140KW |

| Productivity | 1000-1500Kg/h |

| Separation Rate | Above 99.5% |

| Packing | 40'HQ |

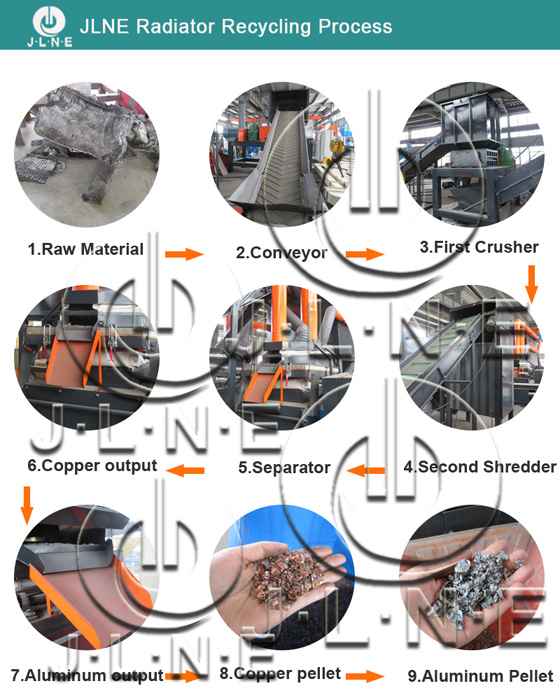

Working principle of Radiator separating line:

Radiator harmless separating and recycling machine,which adopts

dry-type crusher ,magnetic separator and air separator to break and

separate the radiator, turning the radiator into copper, iron and

aluminum. The whole process is conducted in negative pressure.

The equipment needs hand feeding and inside hard material, such as

chunks of iron or large screws, shafts, should be picked out in

advance. Then after first crushing and second crushing, aluminum,

iron and copper are taken off. At last, magnetic separator and air

separator separate aluminum, iron and copper. Pulse dust catching

system is allocated in crushing and separation part, effective

solution to the dust discharge. The crushing and separation system

is equipped with pulse dust collector system, so the dust problem

can be solved.

Main Components of Car radiator separating equipment:

1. Conveyor:Put radiators on the conveyor and send them to first

crusher.

2. First crusher: This crusher cut the radiator to small pieces

with size of 10-15cm

3. Second shredder: The shredder cut the crushed radiator to final

small pieces.

4. Separator: Copper pellet and aluminum pellet get out of this

vibrating separator.

5. Dust collector: includes pulse dust collector and air filter

FAQ:

Q:How many pieces blades inside first crusher? And how long is the

use life?

A:40pcs blades. Uselife: 3-5 years

Q:How many blades inside the second crusher? Uselife?

A:14pcs. Uselife: 1-2 years

Q:How to maintain the blades?

A:We have blade sharpener machine.

You can sharping the blades after use it for time.

Q:How often to sharping the blades?

|