| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | Robot Production Line |

|---|---|

| Brand Name: | Kehui |

| Model Number: | KHGC |

| Certification: | ISO9001, CE, CU-TR |

| Place of Origin: | Henan, China |

| MOQ: | 1 SET |

| Price: | $2000/set |

| Payment Terms: | L/C, T/T, MoneyGram, WestUnion |

| Supply Ability: | 100 sets per month |

| Delivery Time: | 30 days after payment |

| Packaging Details: | in wooden box |

| Welding speed: | 0.6-10 rpm |

Brief introduction

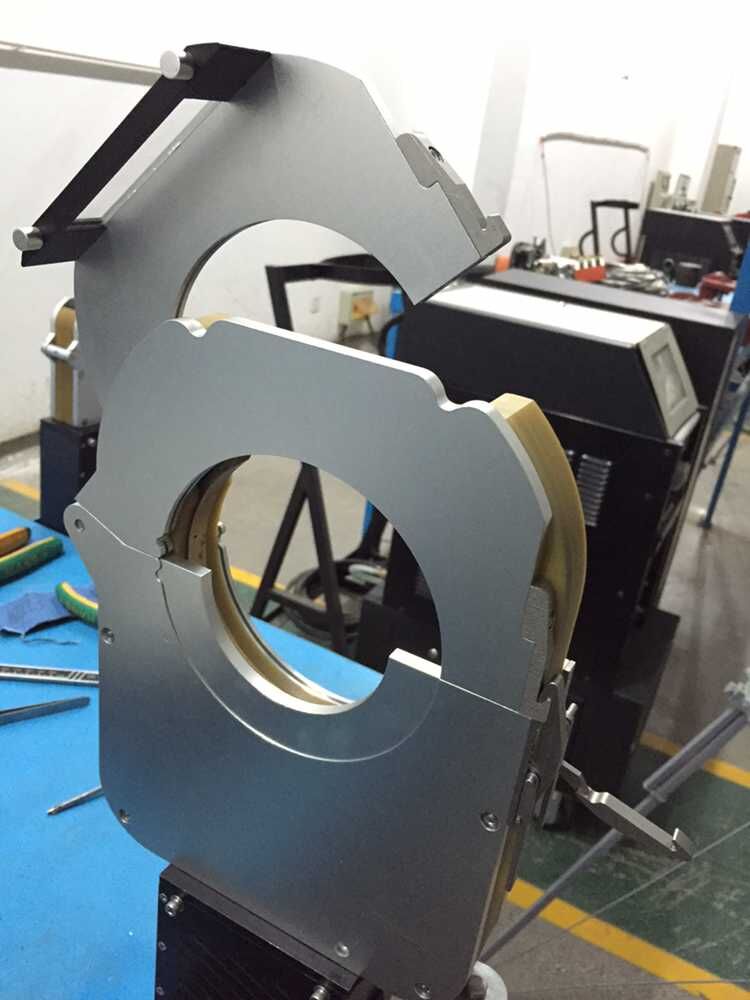

KHGC series Enclosed Head type pipe orbital welding machines can be used for tube outer diameter from Ф3—Ф180mm tube-tube automatic welding at all positions. It is especially suitable for welding carbon steel, alloy steel, stainless steel and titanium alloy thin-walled tubes.

Application

Mainly used in pharmaceutical and chemical industry, food machinery, biological engineering, refrigeration engineering, electronic equipment, etc.

Product Data

Weight : 1.2-9.8kg

Pipe outer diameter: φ3mm ~φ180mm

Protecting air : argon

Capacity of Internal Memory:100 Programmer

Features:

1. Double clamping positioning, good positioning effect, no need to locate spot welding, improve welding efficiency;

2. Pulse power supply, closed design of the welding head, good protection effect, uniform and beautiful weld seam;

3. Lightweight structure design, suitable for assembly site with small space;

Work principle

After completing the welding program setting on the control box panel, place the tube on the positioning cover, close the positioning cover, tighten the rotating sleeve, press the start button on the remote control, start to deliver air in advance, and fill the head cavity with argon. After the gas forms a stable argon gas protection environment, the welder starts to arc, and the current gradually rises from the arcing current to the welding current. At this time, the welding moment does not rotate, and the purpose is to preheat the pipe, and the process can be input through The rise time parameter is used to control. When a stable molten pool is formed on the workpiece, the torch begins to rotate. During the rotation process, there will be flat welding, downslope welding, overhead welding, upslope welding at some time. This welding machine allows the user to set any segmentation of 1~6 segments within 360° according to the situation, and set them separately. Each section of welding speed, current magnitude and other parameters make the weld as a whole consistent. When the welding torch rotates 365° (the lap angle can be set arbitrarily), the welder enters the attenuation program. At this time, the machine head continues to rotate, and the current gradually decreases from the welding current to the arcing current, forming a weld joint. It can be controlled by entering the fall time parameter. The welding process of the entire nozzle is automatically completed according to the setting procedure after the start button is pressed.

Technical parameters

| Suitable Dia (mm) | φ3 mm ~φ180 mm |

| Control Method | IGBT Inverter |

| Rated Input voltage|Phase No. | AC 220V/380V±10% Three Phase |

| Rated Input voltage range | 380 V ± 10 % |

| Rated Input Capacity | 13.9 KVA |

| Rated Input Capacity | 9.5KW |

| Rated Load Sustained Rate | 60 % |

| Rated Unload Voltage | 78 V |

| Rated Welding Voltage | 22.6 V |

| Range Of Input Curren | 5 ~ 300 A |

| Pulse Frequency | 0.5 ~ 500 Hz |

| Pulse Width | 5~95% |

| Rise Time Of Current | 0 ~ 20 s |

|