| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | Glass Fiber Geogrid |

|---|---|

| Place of Origin: | China |

| Brand Name: | Hengquan |

| Certification: | ISO 9001 |

| Model Number: | EGA30-100 KN |

| MOQ: | 1000m2 |

| Price: | Deliberation |

| Packaging Details: | packing belt |

| Delivery Time: | 5-8 days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 40000M2 per week |

| Material: | Glass Fiber |

| Hole size: | 25.4*25.4 mm or 12.7*12.7 mm |

| Width: | 3.95 or 5.95 meters |

| Length: | 100 meters |

| Tensile strength:: | 25Kn/m--120Kn/m |

| Application: | road construction asphalt reinforcement |

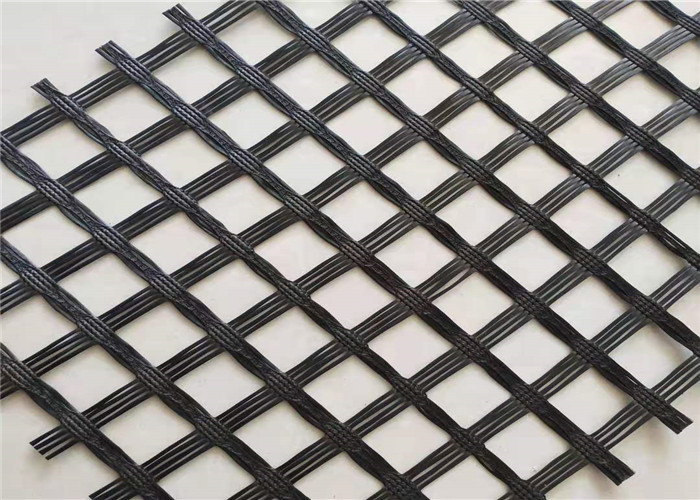

Road Construction Asphalt Reinforcement High Strength Tensile Glass Fiber Geogrid

Glass Fiber Geogrid Introduction

Fiberglass geogrid is a kind of new geosynthetics for the reinforcement of road surface and roadbed.This product is made of fiberglass filament by woving machine imported abroad.After coated,it has features of alkali-resistance.This geogrid is mainly used in new road,soft road surface to enlarge the loading capacity and road maintain to prevent the road crackle.

Glass Fiber Geogrid Specification

specification performance | EGA -25-25 | EGA -30-30 | EGA -40-40 | EGA -50-50 | EGA -80-80 | EGA -100-100 | EGA -50-50-Z Self-adhesive | |

Tensile Strength (KN/m) | warp | 25 | 30 | 40 | 50 | 80 | 100 | 50 |

| weft | 25 | 30 | 40 | 50 | 80 | 100 | 50 | |

| Elongaton% | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |

| Mesh Size (mm) 25.4X25.4 12.7X12.7 | ||||||||

| Width(m) | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | |

Fiberglass Geogrid Application

1.This product is also used to strengthen the soft land,such as highway,railway,airport, irrigation work,and the road bed.

2. Reinforcement of roads and crack prevention.

3. Constructing new roads and repairing damaged sections of asphalt surfaces of roads motorways,parking,airport surface and access ways.

4. Expanding thoroughfares and road lanes.

5. Asphalt reinforcing at locations subject to intensive vehicle braking or accelerating,important junctions,bus stop etc.

The characteristics of glass fiber geogrid are as follows

1. G tensile strength, low elongation - glass fiber geogrid is made

of glass fiber, has a very g resistance to deformation, fracture

elongation is less than 3%.

2. No long-term creep - as a reinforcing material, it has the

ability to resist deformation under long-term load, i.e. creep

resistance is very important. Glass fiber will not creep, which

ensures that the product can maintain its performance for a long

time.

3. Thermal stability: the melting temperature of glass fiber is

above 1000 ℃, which ensures the thermal stability of glass fiber

geogrid in paving operation.

4. Compatibility with asphalt mixture - the coating material of

glass fiber geogrid in the post-treatment process is designed for

asphalt mixture, each fiber is fully coated, which has good

compatibility with asphalt, so as to ensure that the glass fiber

geogrid in the asphalt layer will not be isolated from the asphalt

mixture, but firmly combined.

5. Physical and chemical stability - after coating with special

post-treatment agent, the glass fiber geogrid can resist all kinds

of physical wear and chemical erosion, as well as biological

erosion and climate change, ensuring its performance is not

affected.

Because the glass fiber geogrid is a network structure, the

aggregate in asphalt concrete can run through it, thus forming

mechanical interlocking. 6. This limit hinders the movement of

aggregate, which makes asphalt mixture achieve better compaction

state, better bell bearing capacity, better load transfer

performance and smaller deformation under load.

|