| Sign In | Join Free | My xxjcy.com |

|

| Sign In | Join Free | My xxjcy.com |

|

| Categories | Dry Mortar Production Line |

|---|---|

| Brand Name: | MG |

| Model Number: | MG-3.7 |

| Certification: | CE, ISO, SGS,BV |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | T/T, L/C, Western Union, MoneyGram, D/A, D/P |

| Supply Ability: | 30 sets per month |

| Delivery Time: | 20-25 working days |

| Packaging Details: | Wooden box packing and bubble wrap packing |

| Material: | Carbon Steel |

| Function: | Mixing and packing dry powder material |

| Packing method: | Valve packing or open packing |

| Installation service: | engineer to oversea for guiding installation |

| Chemical: | Provide as requirement |

| After-sales services: | Field maintenance,Video technical support |

| Control system: | Computer and PLC control |

| Color: | Customer's Request |

| Batching and weighting: | Automatic System |

| Company Info. |

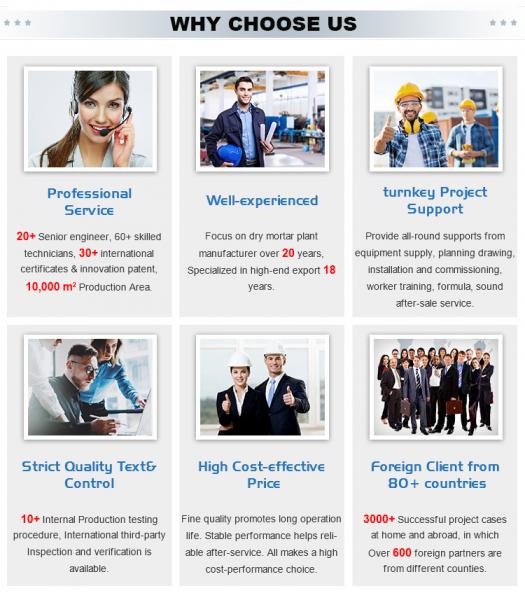

| Zhengzhou MG Industrial Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Industrial Sand Cement Mixing Plant

Building Material Mixing Machinery

1. Decription

We specialize in the production of 3-25t/h dry mortar mixing equipment with 17 years of rich production experience. We will provide you with a complete solution from design solutions, product processing, waterproof packaging, delivery to installation, and training. We will also provide you with long-term after-sales service and technical support, so that you have no worries.

According to your capacity requirements, we will provide you with different optimized configuration solutions to maximize your investment savings. We have the following options for your reference:

Wet Sand Drying System: equipped with Triple-cylinder dryer to reduce the sand water content to ≤0.5%;

Raw Materials Storage System: store all kind of raw materials ;

Lifting & Conveying System: Bucket Elevator, Belt Conveyor, Screw Conveyor, Crane;

Weighing System: depending on different formulas, weighing in proportion accurately;

Mixing System: with 60~180s blending, materials are mixed evenly;

Bagging System: end products are packed by 25/50/1000kg bags, or stored in silos, or delivered by bulk tank truck directly;

Dust Collection System: collect dust from drying system, weighing system, mixing system, packing system, protect the working and living environment.

Control System: Semi-auto/Full-auto Control, convenient for operation and management.

2. Product Technical Parameter

| Model | Simple dry mortar mixing equipment | Improved Simple dry mortar mixing equipment | Semi-automatic dry mortar mixing equipment | Fully automatic dry mortar mixing equipment |

| Out put | 3t/h | 4-5t/h | 6-8t/h | 10-30t/h |

| Occupied area | 20m2 | 20m2 | 50-60m2 | 60-100m2 |

| Equipment height | 3-4m | 3-4m | 6-8m | 8-13m |

| Manpower | 2-3 Person | 2-3 Person | 3-4 Person | 3-4 Person |

| Batching and packaging | Manual batching Automatic packaging | Manual batching Automatic packaging | Manual batching Automatic packaging | Automatic batching Automatic packaging |

3. Production Line Abroad

4. About Us:

6. Packing & Shipping

|